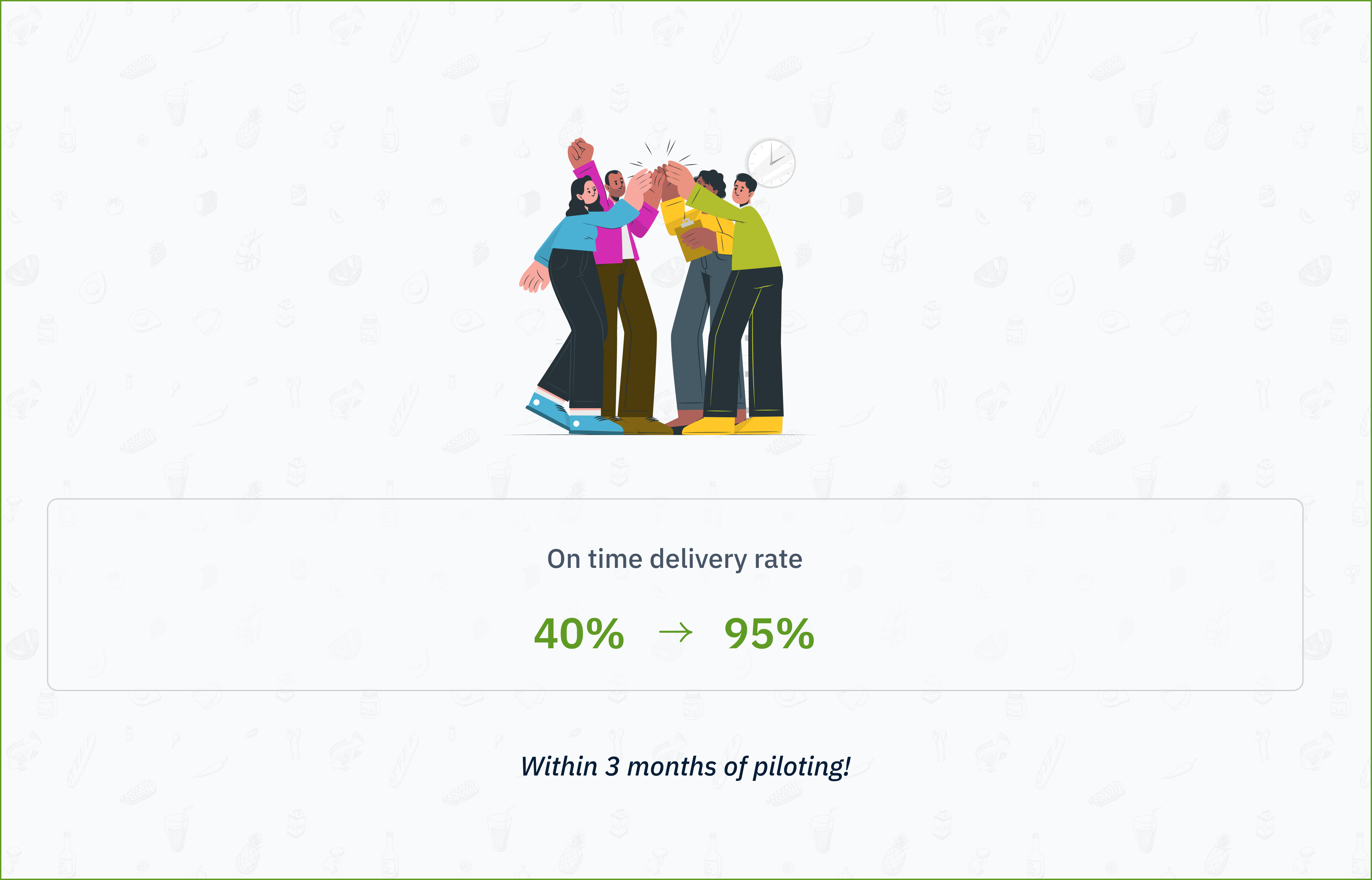

A case study on driving efficiency in order fulfilment for GoLemon, a grocery delivery startup in Lagos, Nigeria.

In a 3 week project, I led the design of an operations management system for a grocery delivery startup. This project involved conducting research to understand the problems and the requirements for the system, mapping the fulfilment operations process to identify inefficiencies with the current system, ideating solutions, and conducting usability testing to validate the solutions.

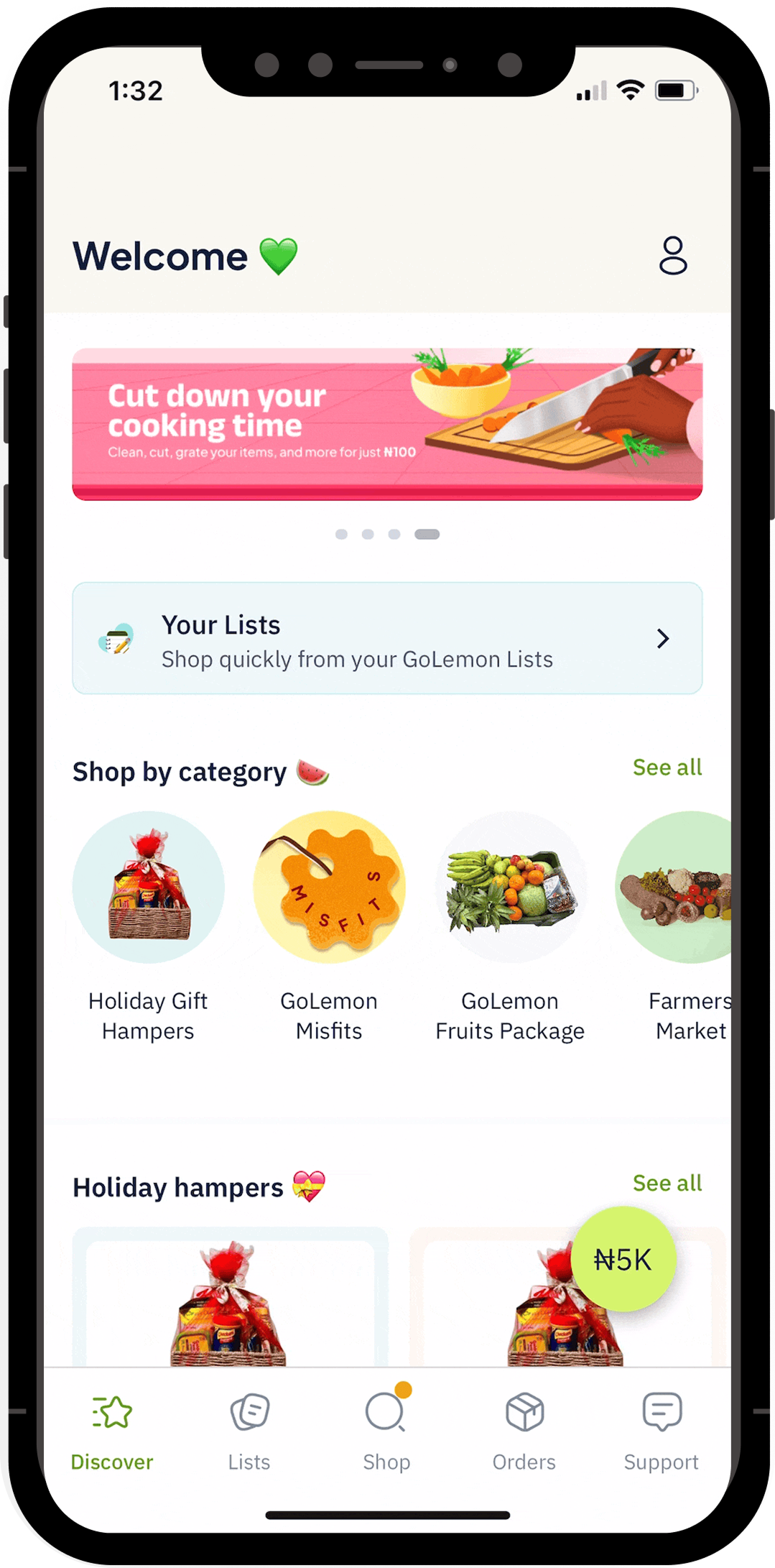

GoLemon is a grocery delivery startup based in Lagos, Nigeria. When GoLemon launched in March 2024, most of the product, design and engineering efforts were around improving the consumer app experience.

As the founding product designer on the team, I worked closely with the engineering team and the founder to launch some exciting features like:

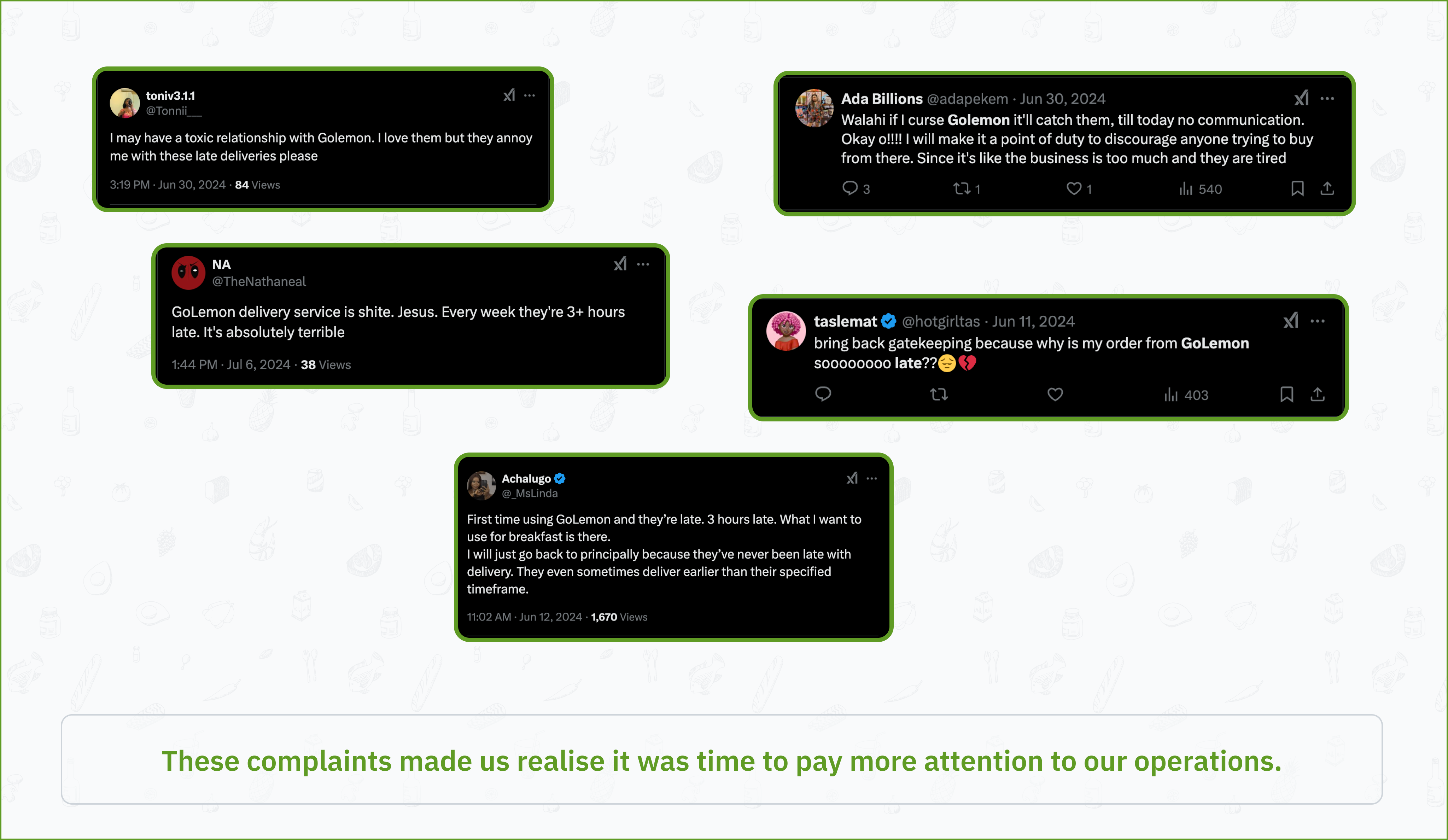

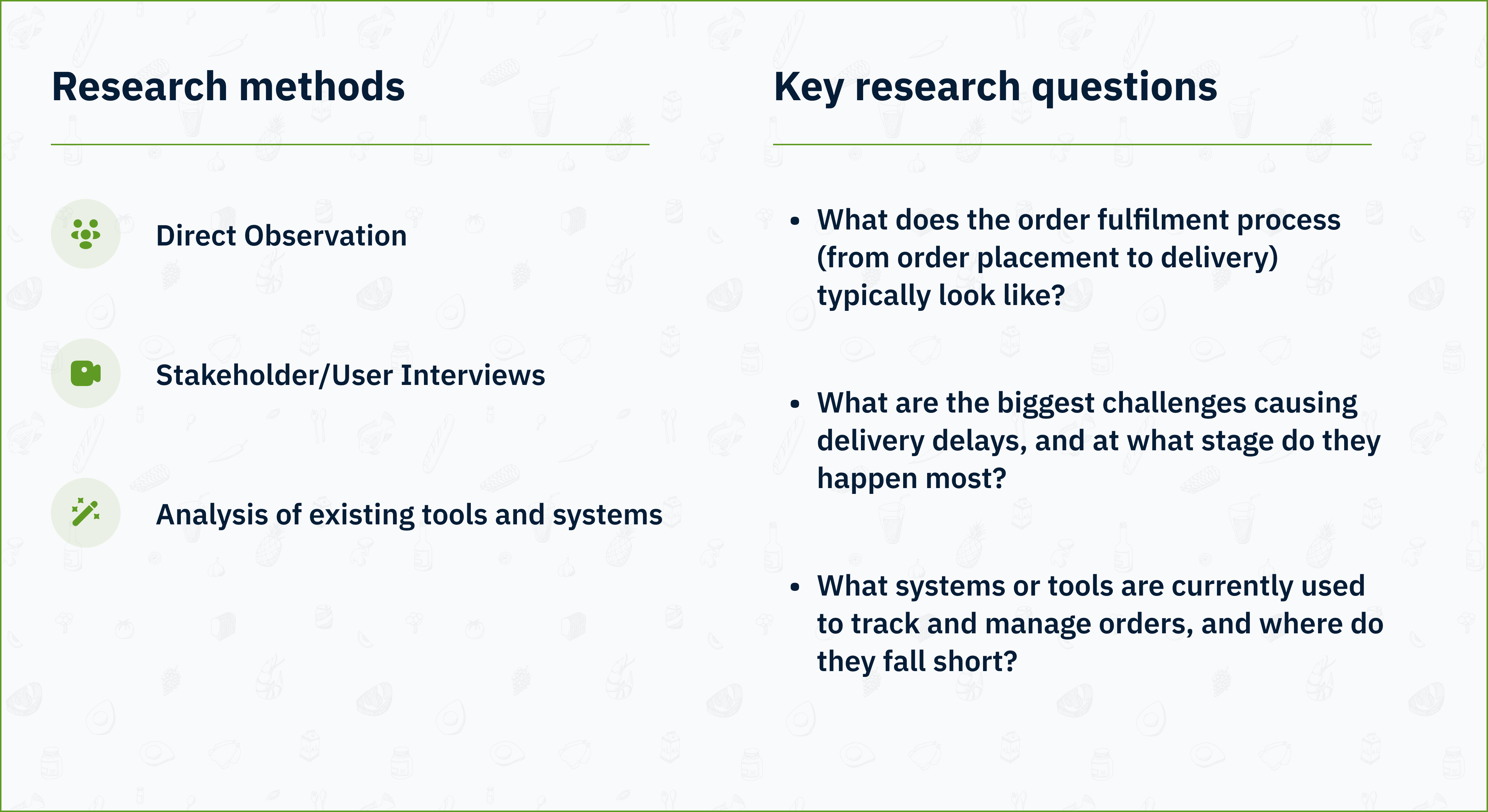

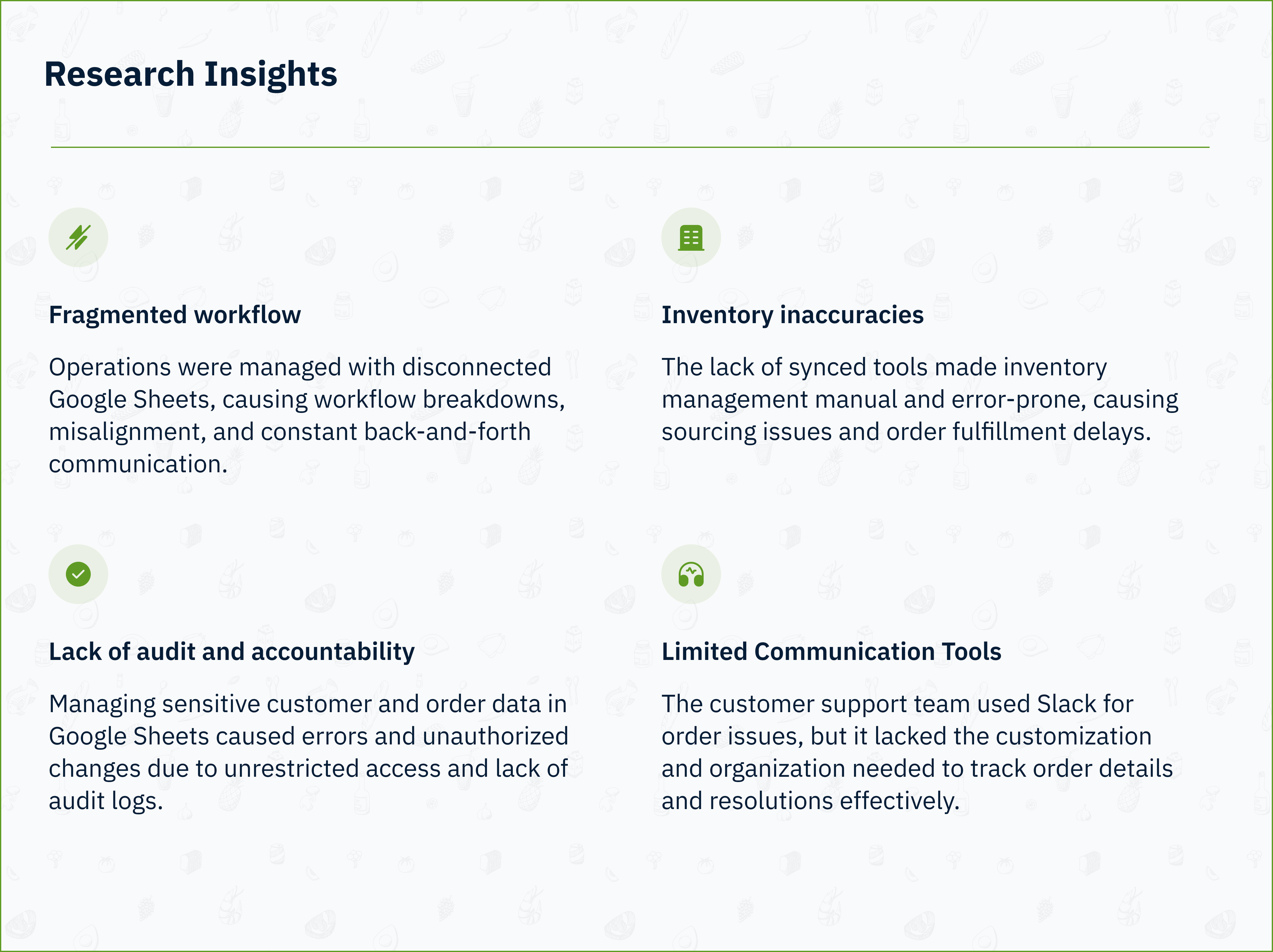

UNDERSTANDING THE PROBLEM THROUGH RESEARCH

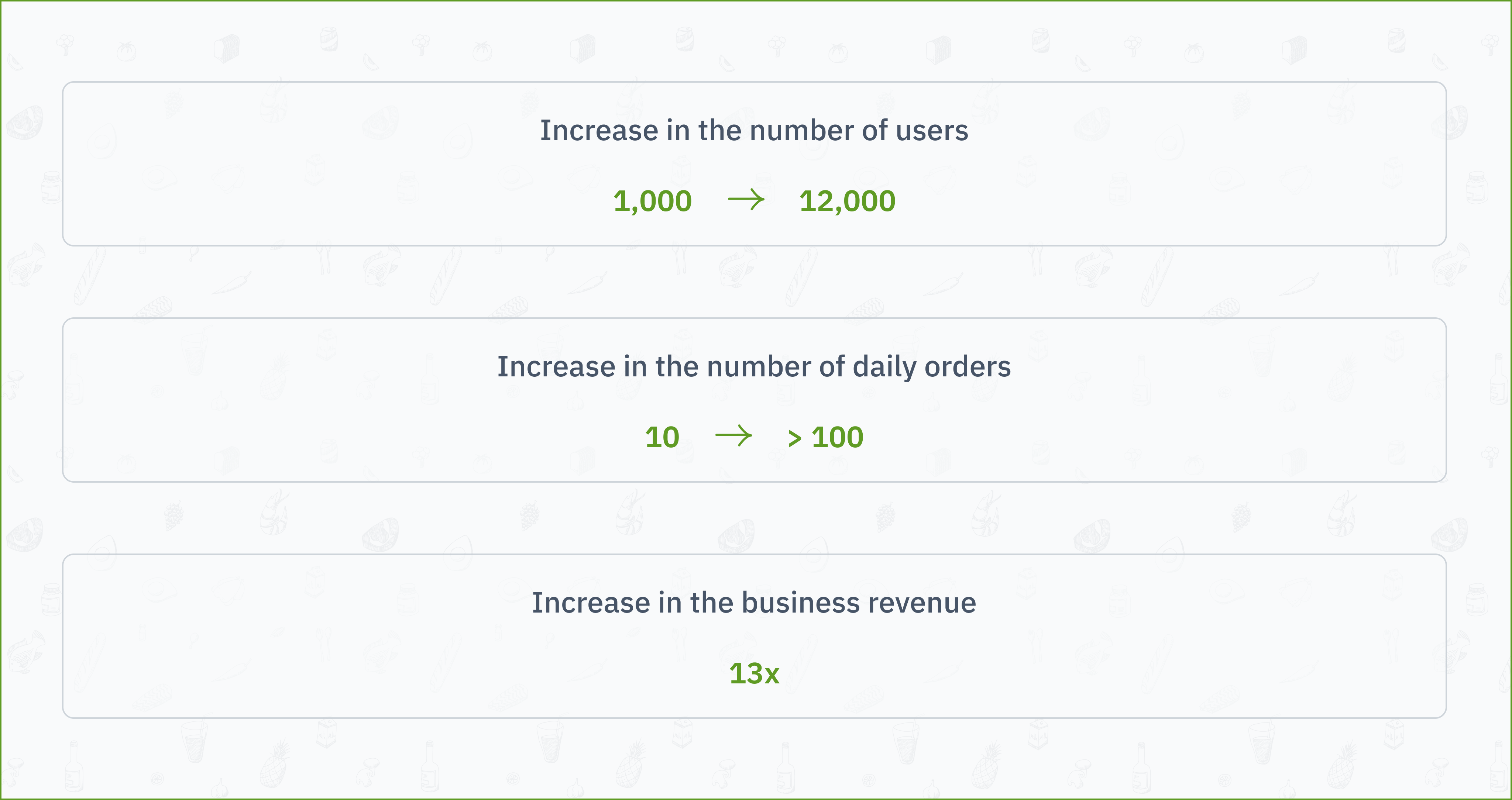

The first step was identifying challenges in GoLemon’s fulfilment process and their impact on customer experience..

For the type of scale we were experiencing, and what we predicted to have, we needed a system that was smarter, more automated and more efficient.

PROCESS MAPPING & USER FLOWS

We mapped out the fulfilment process based on our research, which helped us to visualize the inefficiencies and unnecessary steps, and find areas where technology could help speed things up.

Process map of the order fulfilment flow (Slightly blurred for confidentiality)

From there, we defined product/design opportunities and requirements.

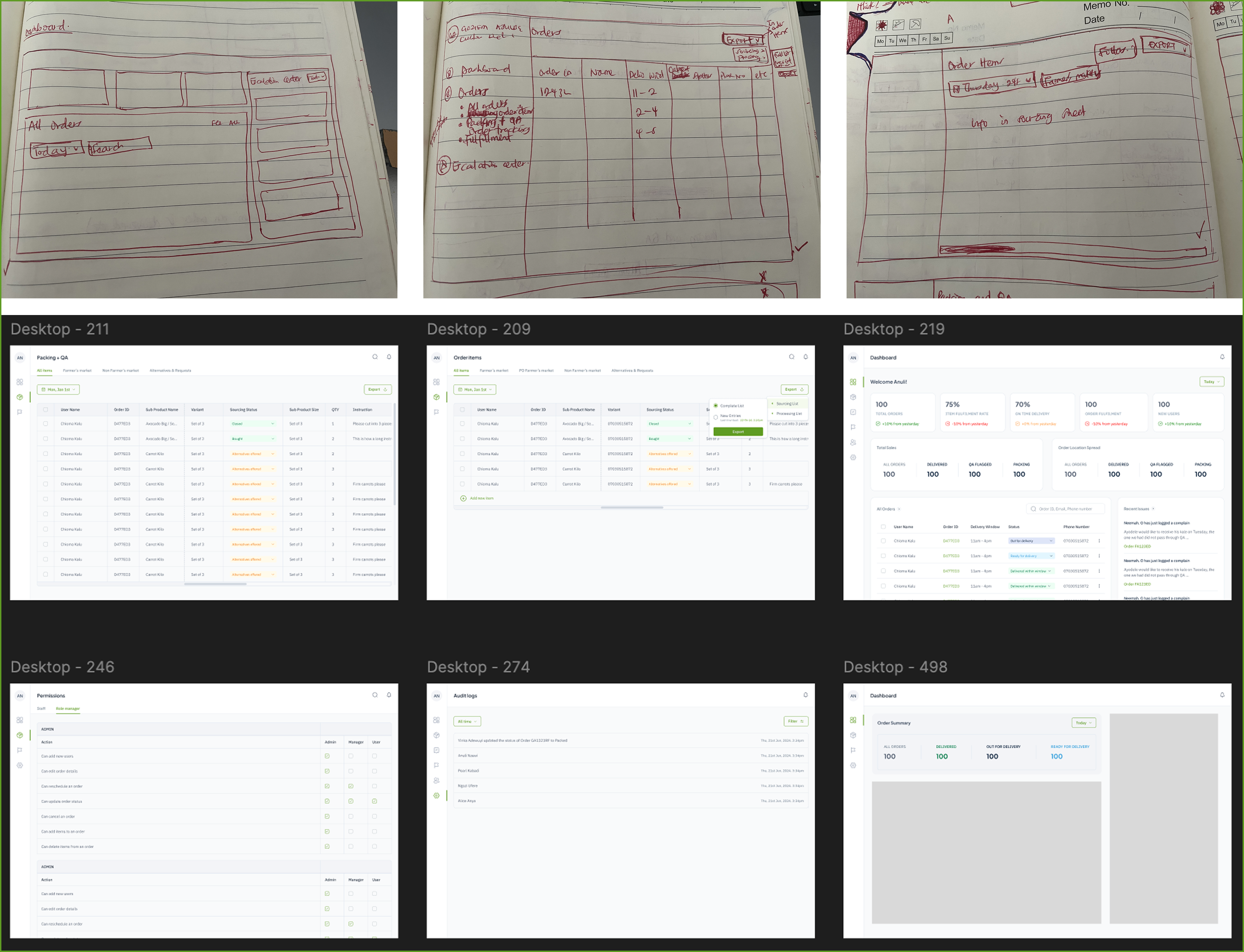

SKETCHES & MID FIDELITY WIREFRAMES

The goal was to complete the design within 3 weeks to enable the engineering team to start development promptly.

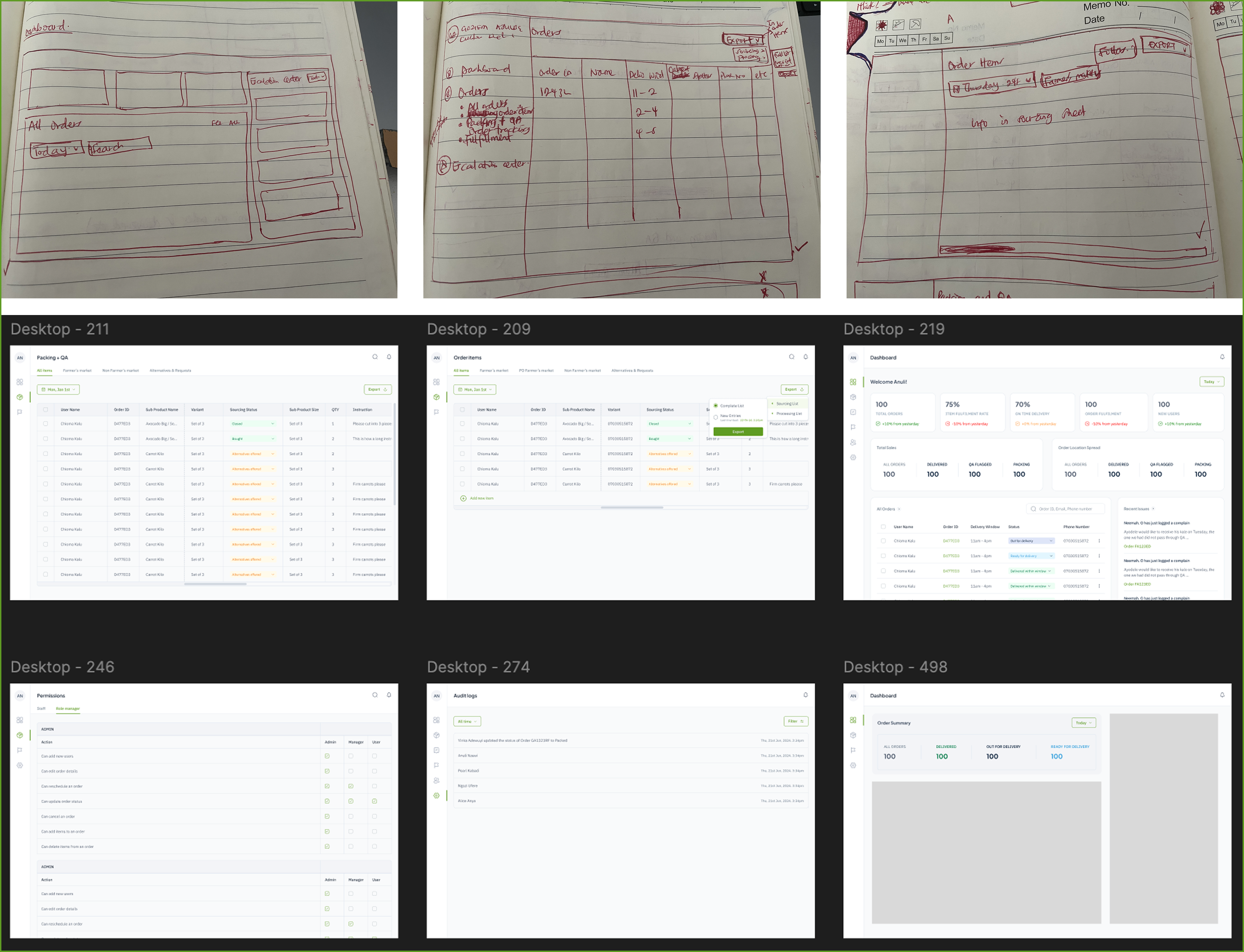

To begin, I created rough paper sketches of key flows to outline my ideas, gather quick feedback on section relevance, and the best arrangement for the different teams that would use the tool.

Sketches and Mid fidelity wireframes

SOLUTION & DESIGN EXECUTION

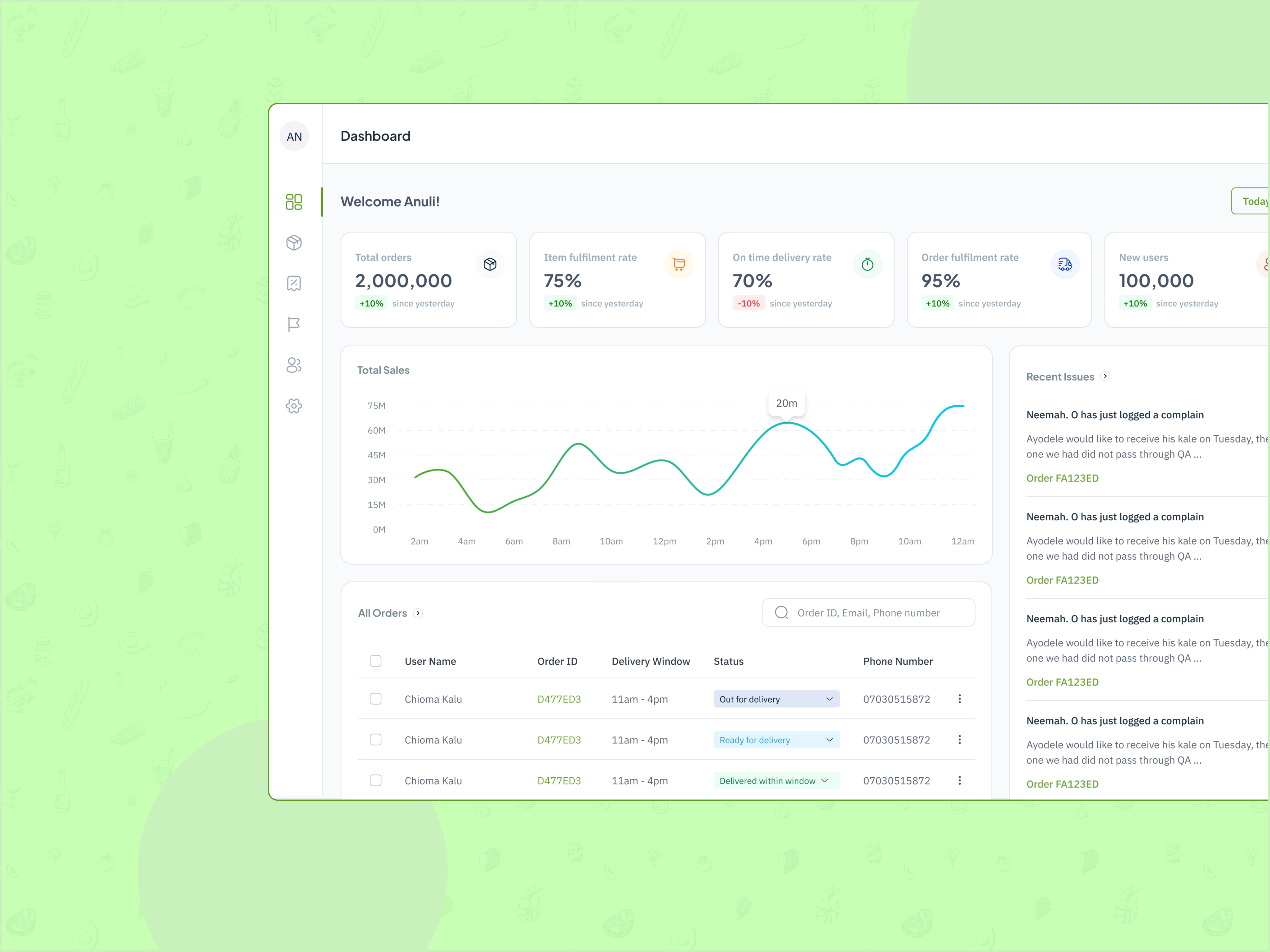

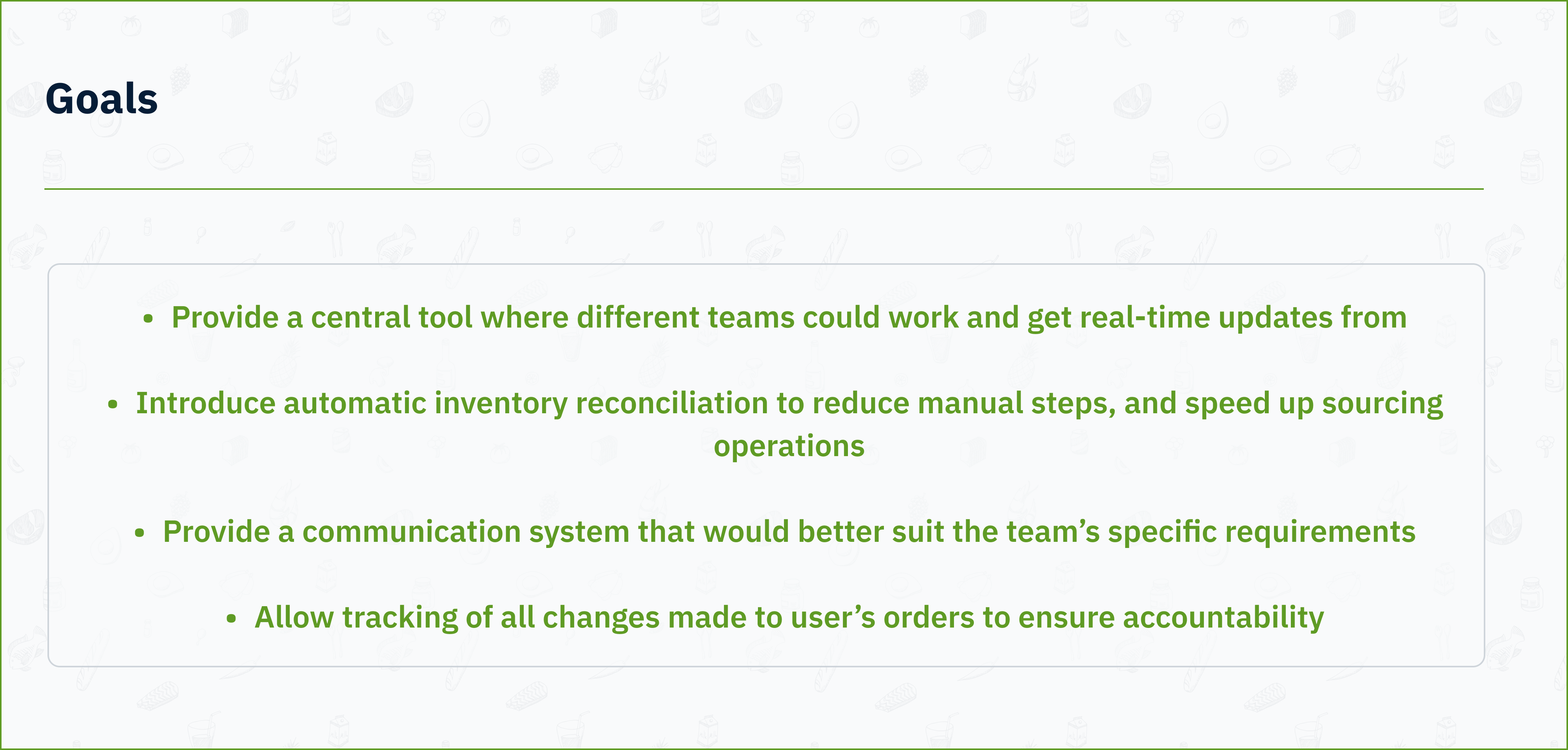

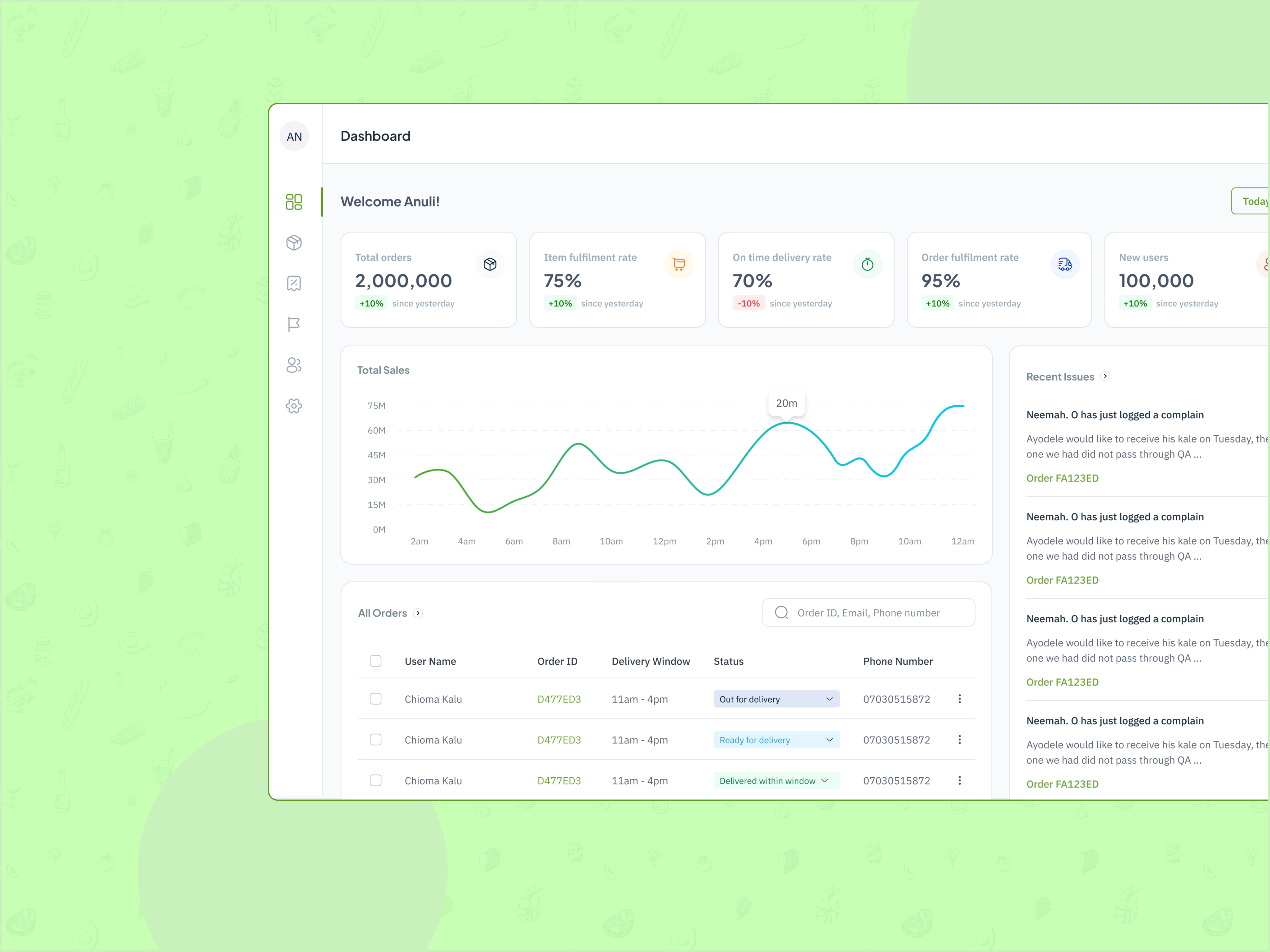

Goal 1: Provide a central tool where different teams could work and get real-time updates from

Identified user issue:

Teams were working from different google sheets that were not speaking to each other. This was leading to misalignment and constant back and forth between teams.

Design solution:

With Limelight, I combined all the fragmented google sheets into an order management system divided into clear sections: Sourcing, Processing, and Packing & QA.

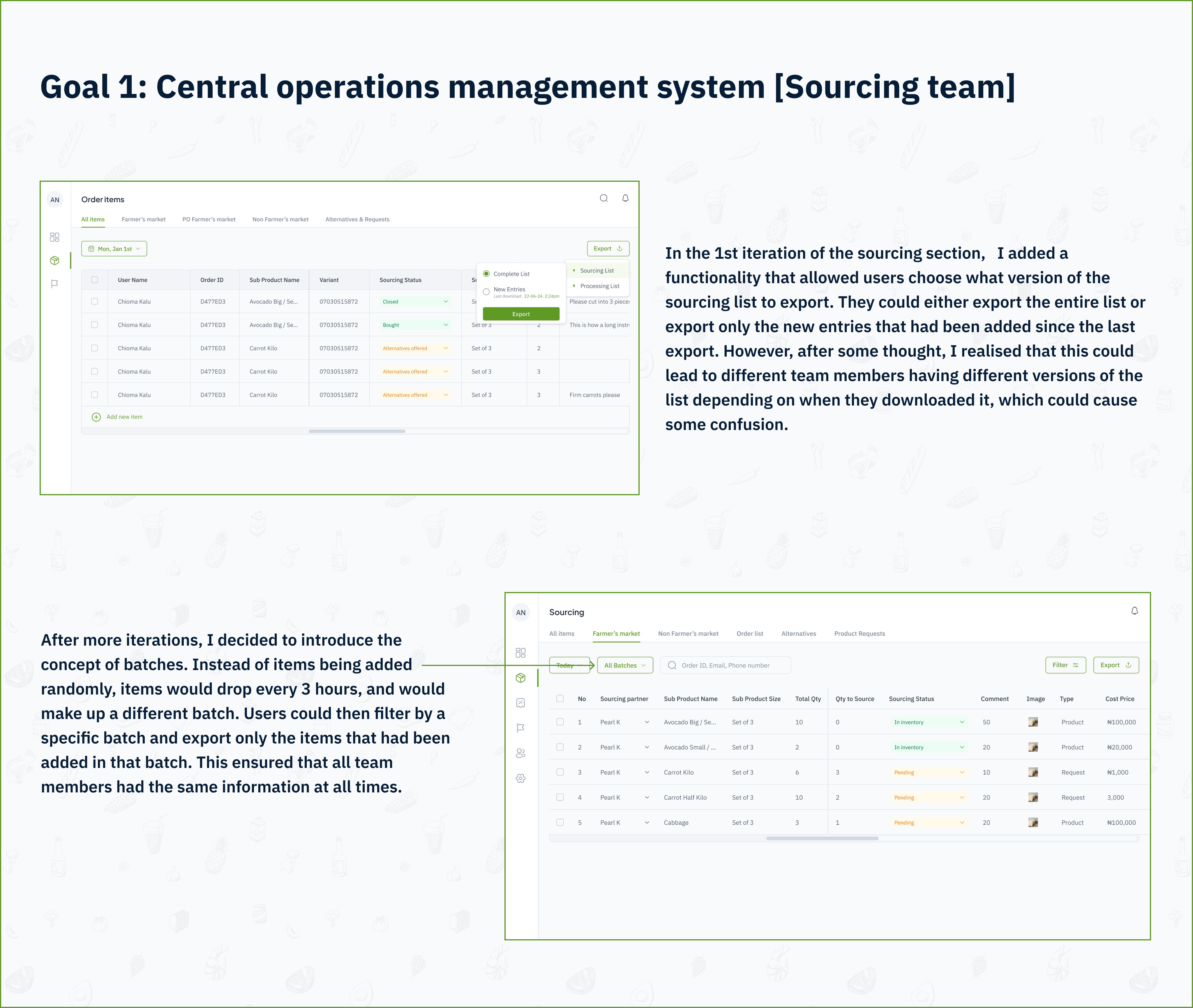

Sourcing section:

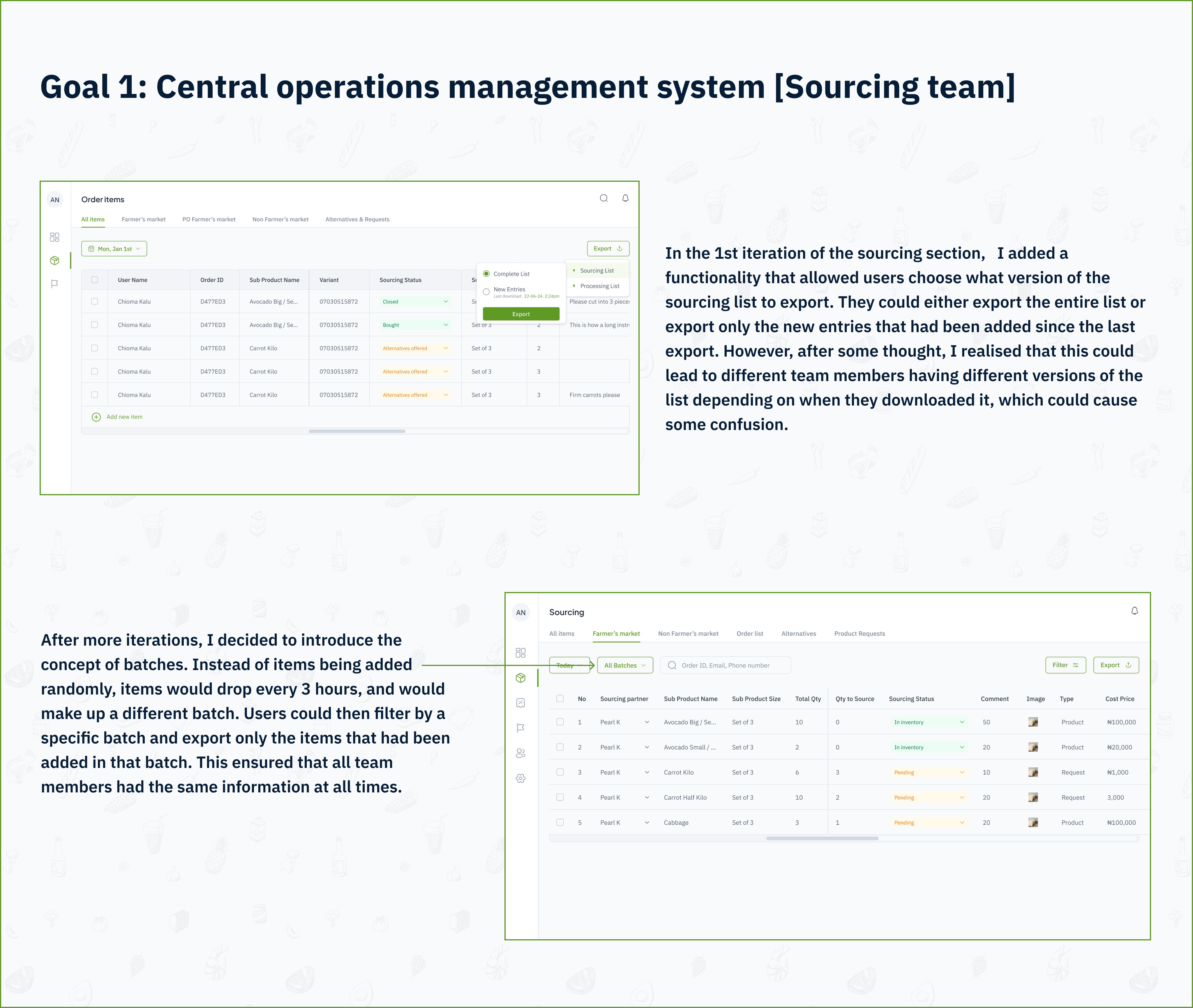

This section of Limelight showed the sourcing team the items needed to fulfil orders on a specific day. In this section, the Sourcing team lead could assign partners to specific items, and every team member could know the status of each item needed.

Items were added to the sourcing section at different times during the day, and a key requirement for the Sourcing team was the ability to know which items had just been added to the sheet.

1st and final versions of the Sourcing section of Limelight

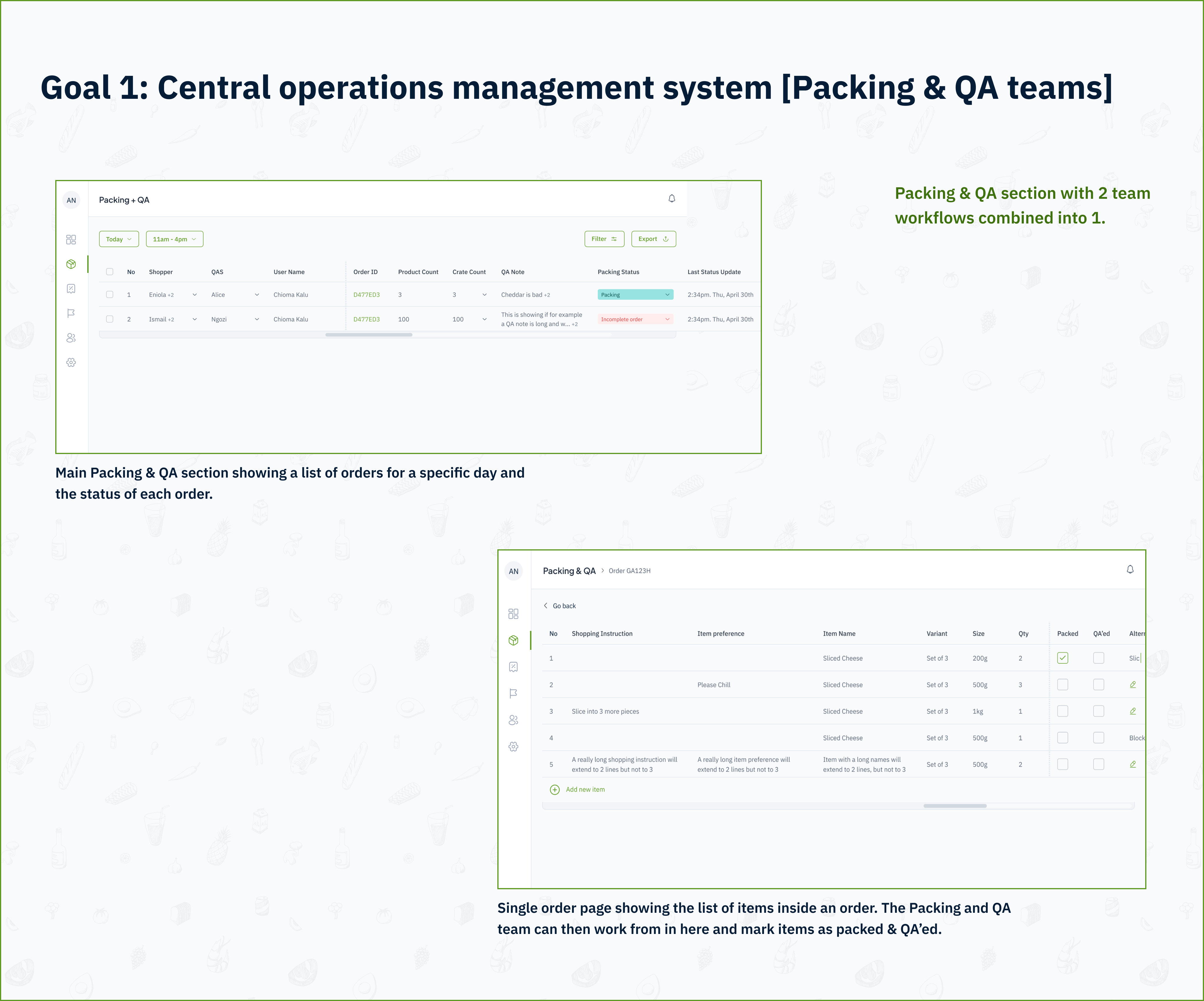

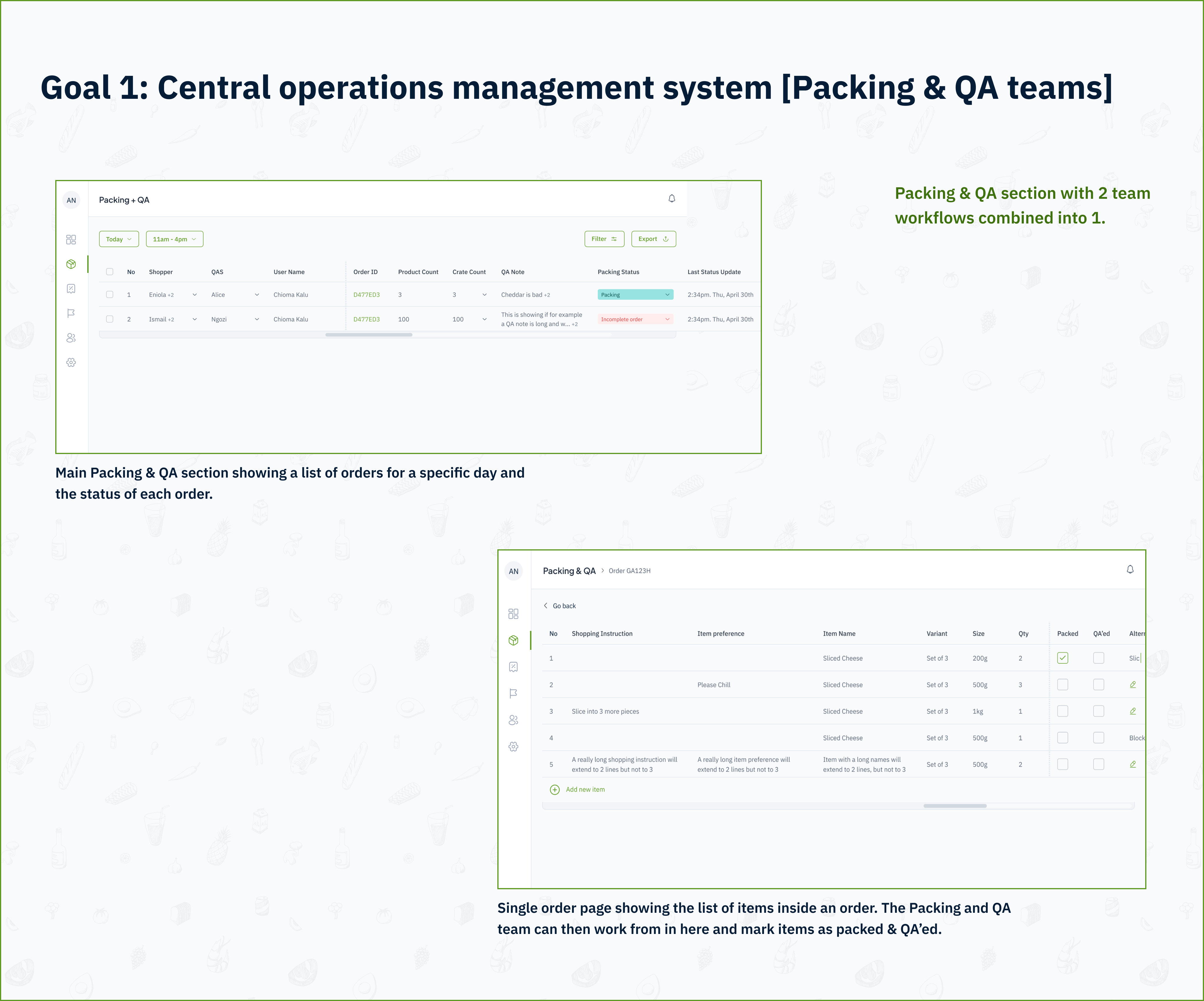

Packing & QA section:

In this section, I combined 2 team’s workflows into one. In this section, the packing team could mark items as packed and update the status of the order. The QA team could come to this section, see the status of each order and be able to tell which orders were ready for quality assurance. They could then work within this same section and update order statuses to Ready for delivery.

A key addition to the Packing and QA section was the “Last status update” column which allows each team member know the last time an order’s status was updated. This helped the Customer support team better manage user expectations on when their order would arrive.

The Packing and QA section on Limelight

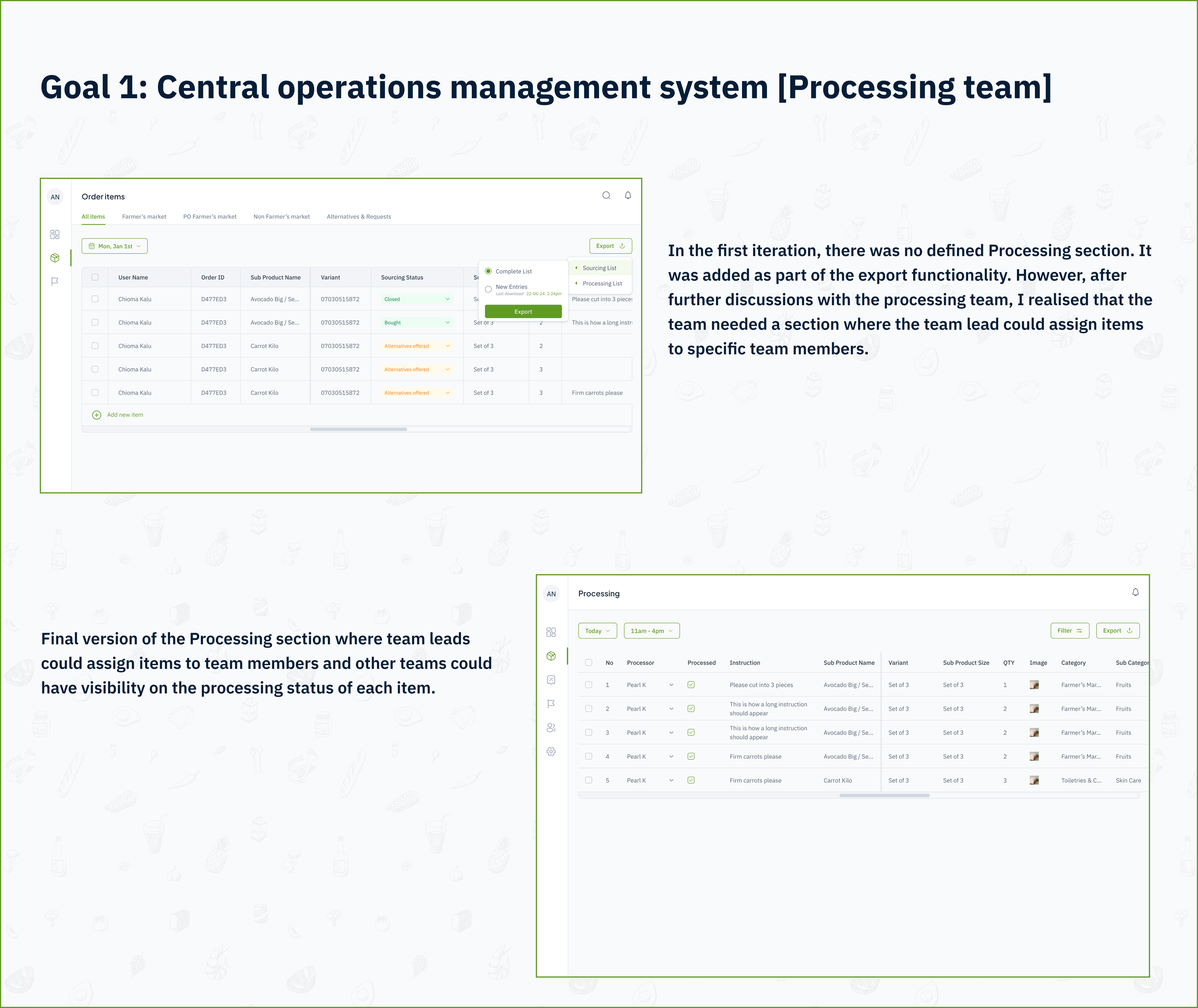

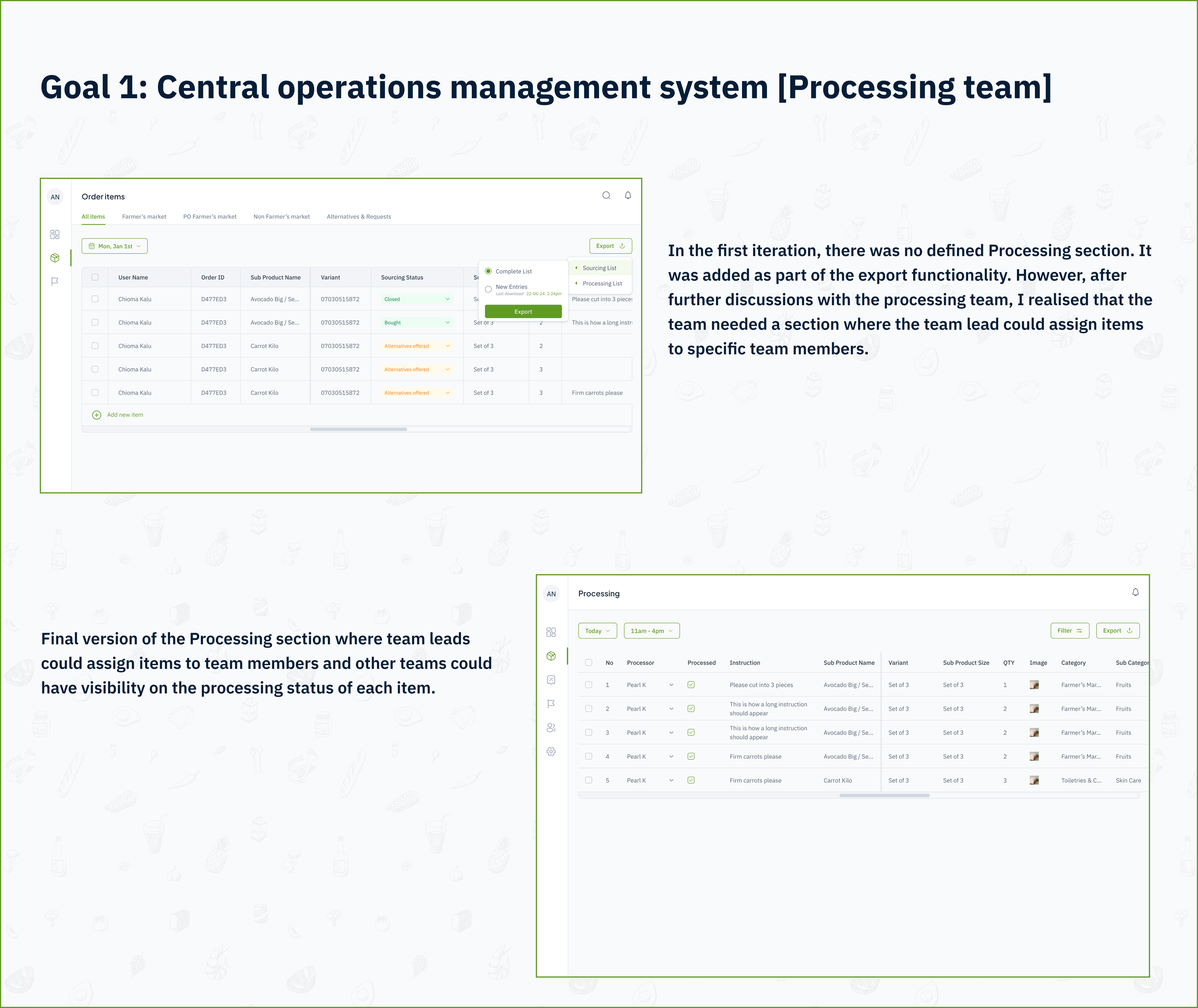

Processing:

In this section, the processing team could see order items that needed to be processed (chopped, diced, blended etc.)

First and final versions of the Processing section on Limelight

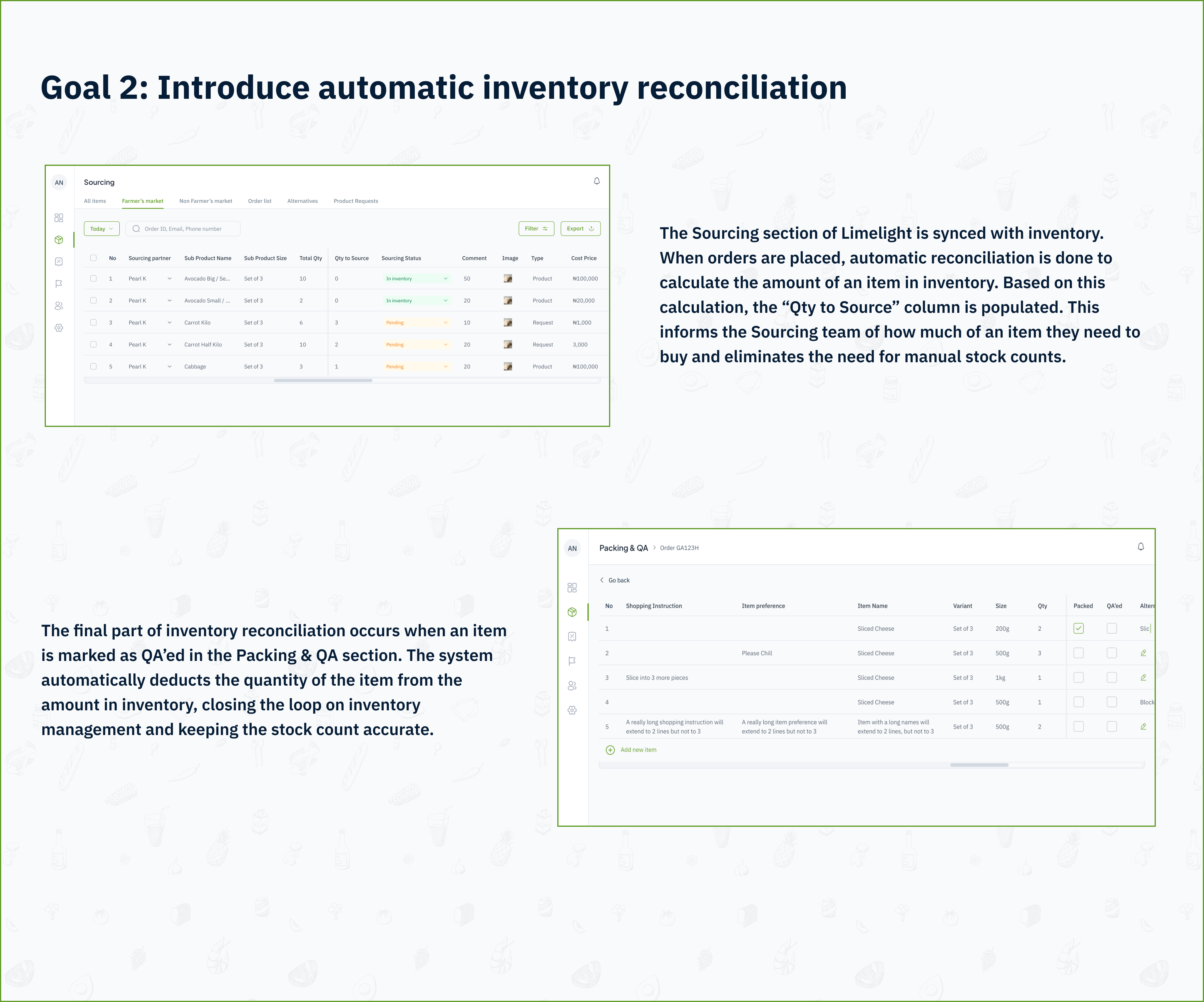

Goal 2: Introduce automatic inventory reconciliation

Identified user issue:

Inventory management was handled by a 3rd party inventory management system, and this system was not integrated with the google sheets used by the other teams to manage their part of the fulfilment process. This meant that although the IMS held records of items coming into the company, there was no automatic reconciliation when those items were leaving and being delivered to customers. As a result of this, stock counts had to happen manually every day further delaying the fulfilment operations process.

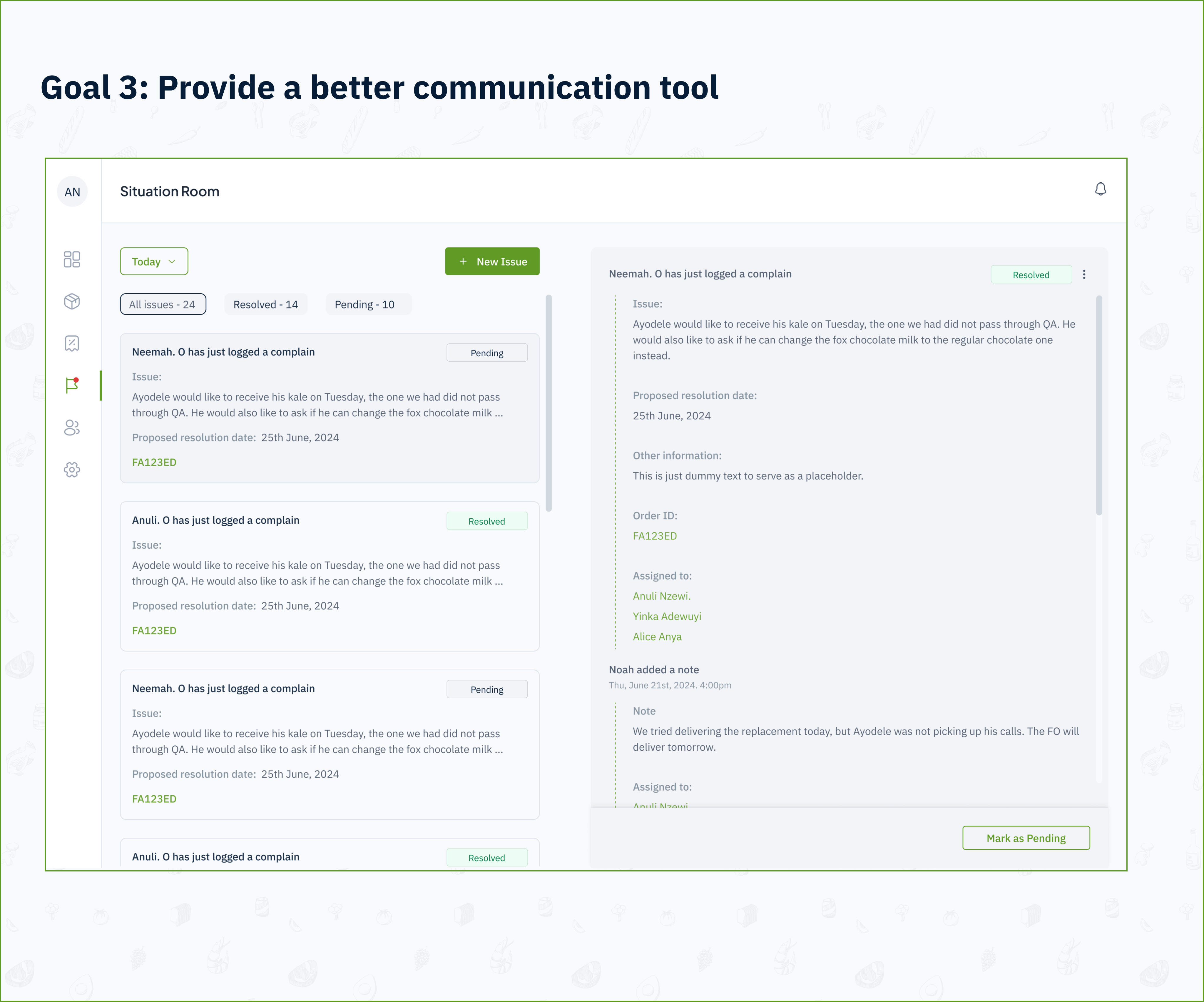

Goal 3: Provide a communication tool that would better suit the team’s specific requirements

Identified user issue:

Slack lacked the customization needed to track order details and resolutions effectively. This caused Customer support agents and other team members to frequently miss escalations about a user’s order leading to disgruntled customers.

Design solution:

I introduced the “Situation Room” which replaced Slack as the main communication hub for the customer support team. It allows teams to log and track customer issues in real time, providing greater context and improving collaboration.

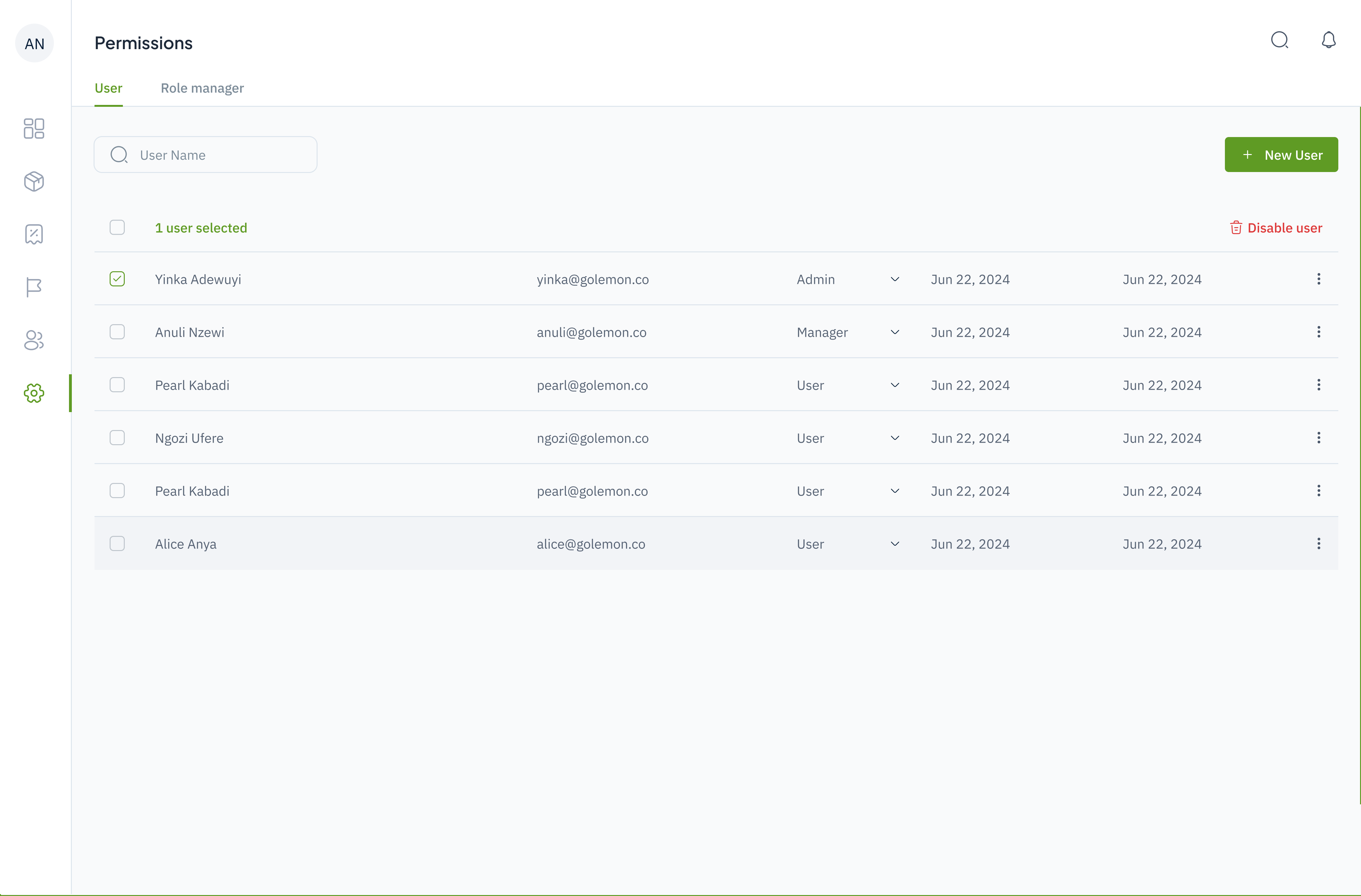

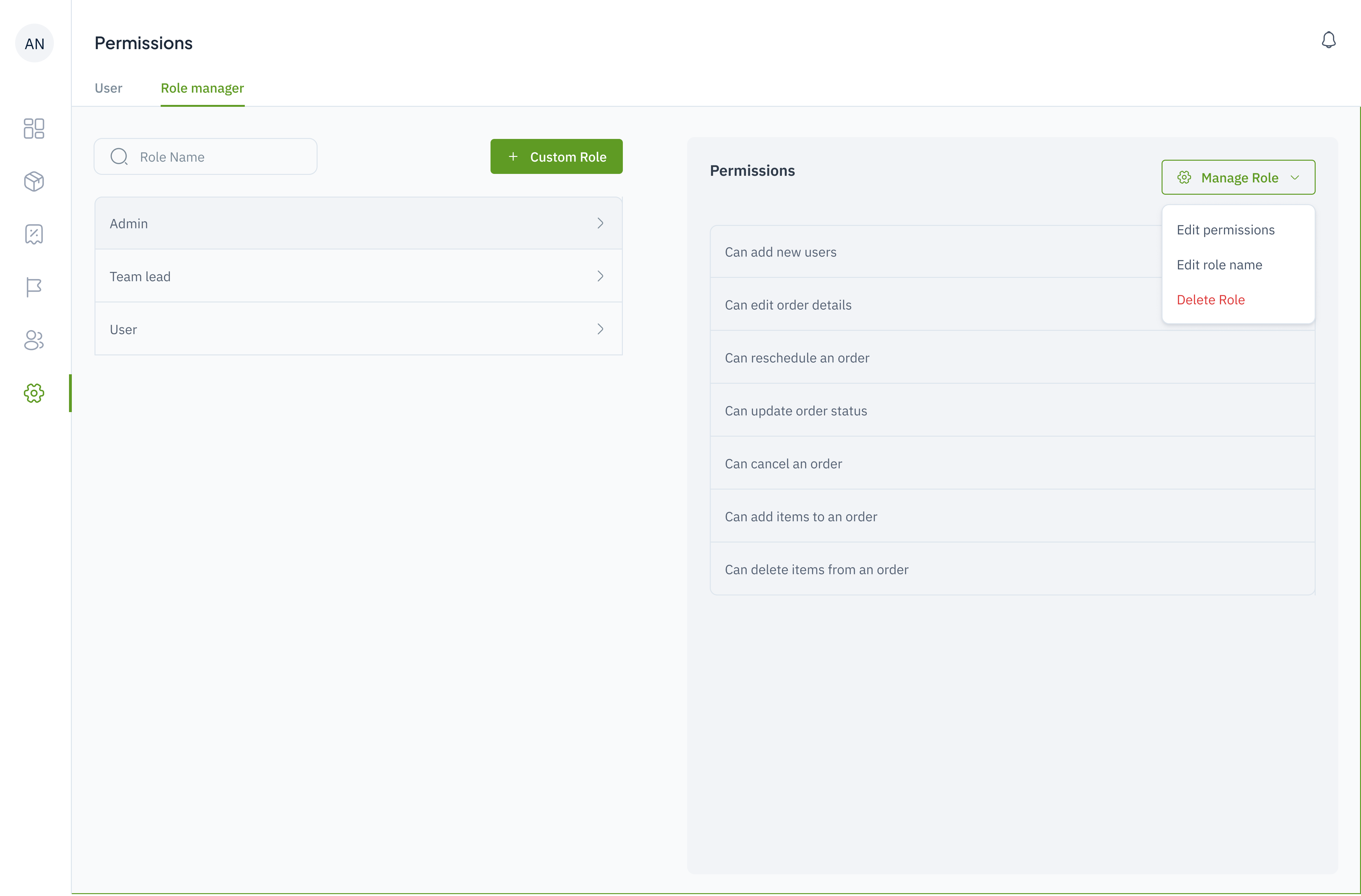

Goal 4: Allow tracking of all changes made to a user’s order to ensure accountability

Identified user issue:

Managing sensitive customer and order data in Google Sheets caused errors and unauthorized changes due to unrestricted access and lack of audit logs.

Design solution:

I introduced a robust system of roles and permissions, allowing administrators to restrict access to specific data based on user roles. The audit logs tracks every change made in the system, providing accountability and ensuring that unauthorized changes are easily traced.

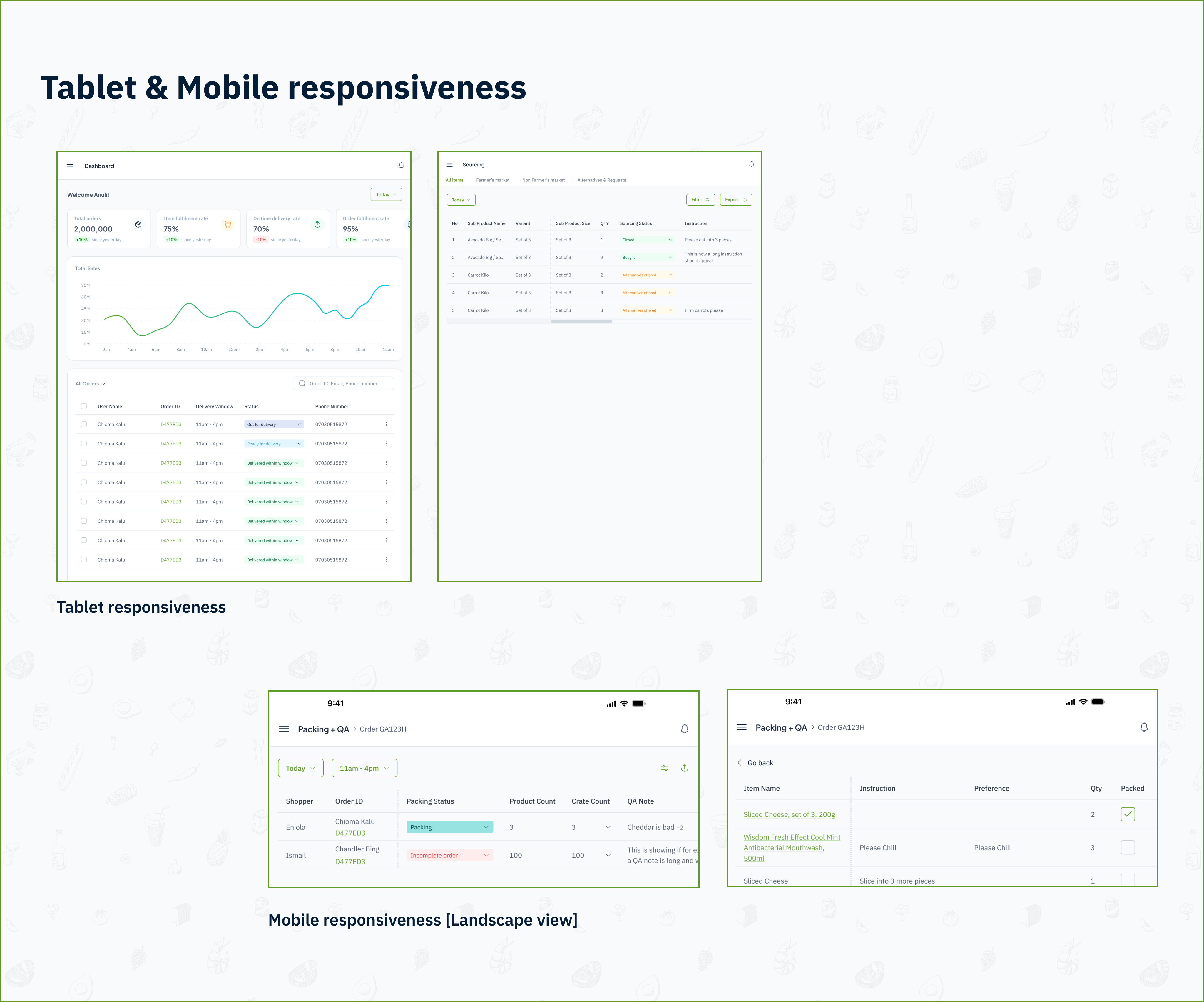

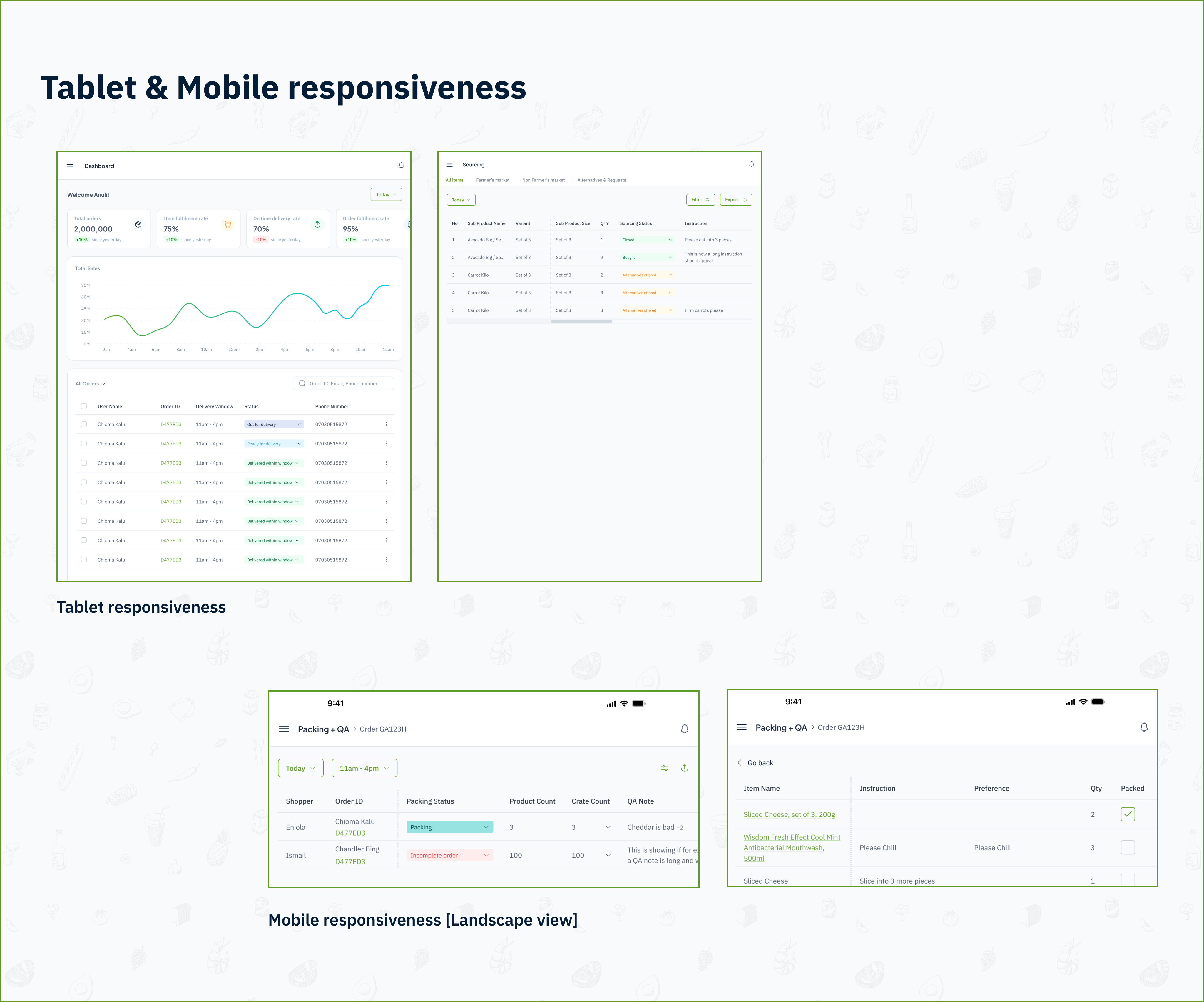

As part of this project, I also worked on tablet and mobile responsiveness for the Web application.

Tablet and Mobile responsiveness

USABILITY TESTING & DESIGN UPDATE

After working on the design, I conducted demos and usability testing sessions with stakeholders across operations, engineering and customer support. From these conversations, we made some updates to the design to improve the accuracy and experience.

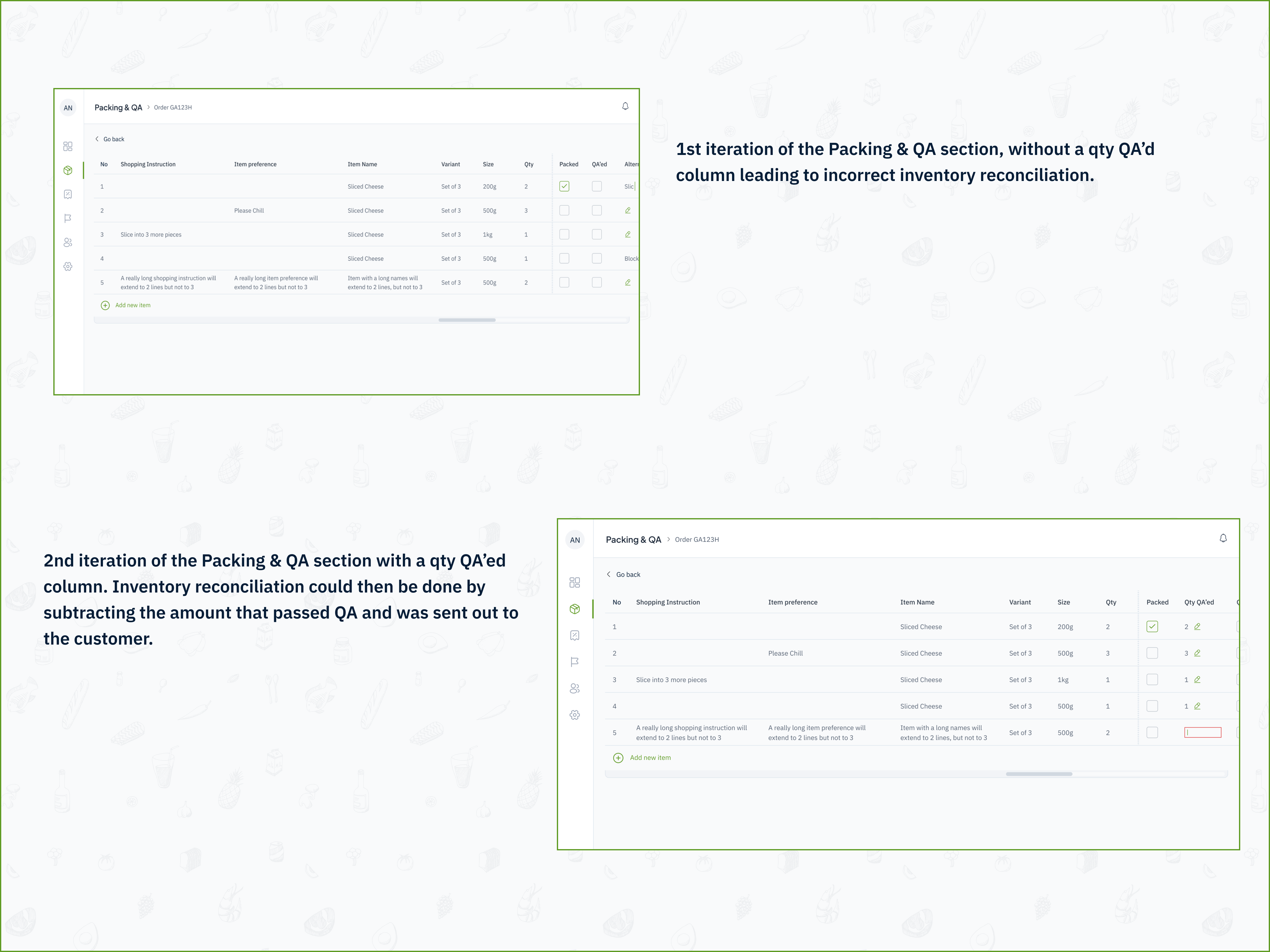

Introduced a quantity QA’ed column

In the first iteration, inventory reconciliation was done by subtracting items that had been marked as QA’ed from inventory. However, the fulfilment operations team shared that in some cases, the amount of items sent to customers were less than the original amount paid for in the order, due to quality assurance checks. To ensure that we were deducting the correct amount that left inventory, we introduced a qty QA’ed column.

CHECK OUT MY NEXT PROJECT

Panda

Designing “Canva for Paystack”

UX Research. Design.

Content guide