GoLemon shifted from 2-day to next-day delivery, revealing major inefficiencies in their existing order fulfilment process, which was managed via spreadsheets and Slack. This fragmented system:

- Lacked real-time visibility into order status, causing delays and confusion across teams.

- Relied heavily on manual data entry, resulting in frequent inventory inaccuracies.

- Used Slack for issue tracking, which was disorganized and inadequate for order-specific communication.

With rapidly growing order volume and operational complexity, GoLemon needed an automated, centralized platform to streamline fulfillment, reduce errors, and facilitate team collaboration.

ROLE

Lead product designer

CONSTRAINTS & LIMITATIONS

- Time

- Limited Resources

RESEARCH & USER INSIGHTS

To shape Limelight’s design, I partnered with the product manager and conducted research using multiple methods that included:

- User interviews across the Sourcing, Packing, QA, Support, and Engineering teams to identify pain points and workflow bottlenecks

- Observation of fulfillment teams during their day-to-day work to understand their daily challenges and communication gaps

- Analysis of existing tools to understand their shortcomings

Key research questions

- What does the order fulfilment process (from order placement to delivery) typically look like?

- What are the biggest challenges causing delivery delays, and at what stage do they happen most?

- What systems or tools do you currently rely on to track and manage orders, and where do they fall short?

Key Insights

- Teams operated in silos with disconnected systems, creating misalignments and manual back-and-forth

- Manual inventory management led to frequent stock discrepancies delaying order fulfilment

- The customer support team relied on Slack to communicate issues related to orders, but Slack lacked the customisation and organisation needed to track specific order details and resolutions.

OBJECTIVE

"How can we centralise and automate the order fulfillment process, to improve operational efficiency, reduce errors, and enhance communication across teams?"

SYNTHESIS

Process mapping & brainstorming

We mapped out the fulfilment process based on our research, which helped us to visualise the inefficiencies and unnecessary steps, and find areas where automation could speed things up. From there, we defined product/design opportunities and requirements.

Process map of the order fulfilment flow (Slightly blurred for confidentiality)

Product/Design requirements

- Introduce automatic inventory reconciliation to reduce manual steps, and speed up sourcing operations.

- Provide a central tool where all the different teams could work, and get updates from.

- Provide a communication system that would suit the team's specific operations requirements better.

SOLUTION & DESIGN EXECUTION

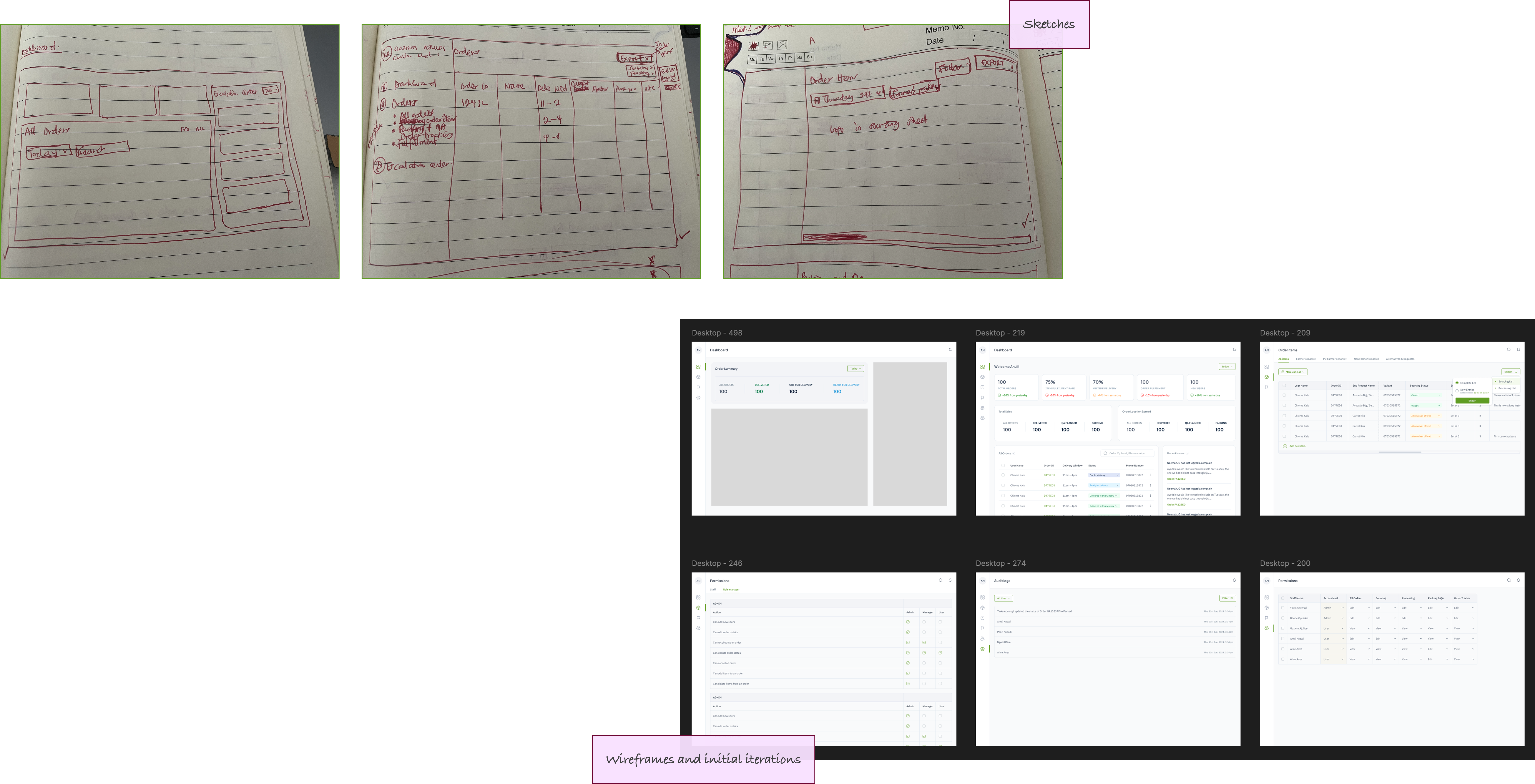

Sketches and initial ideas

Collaborating deeply with product and engineering, I designed Limelight with the following core features:

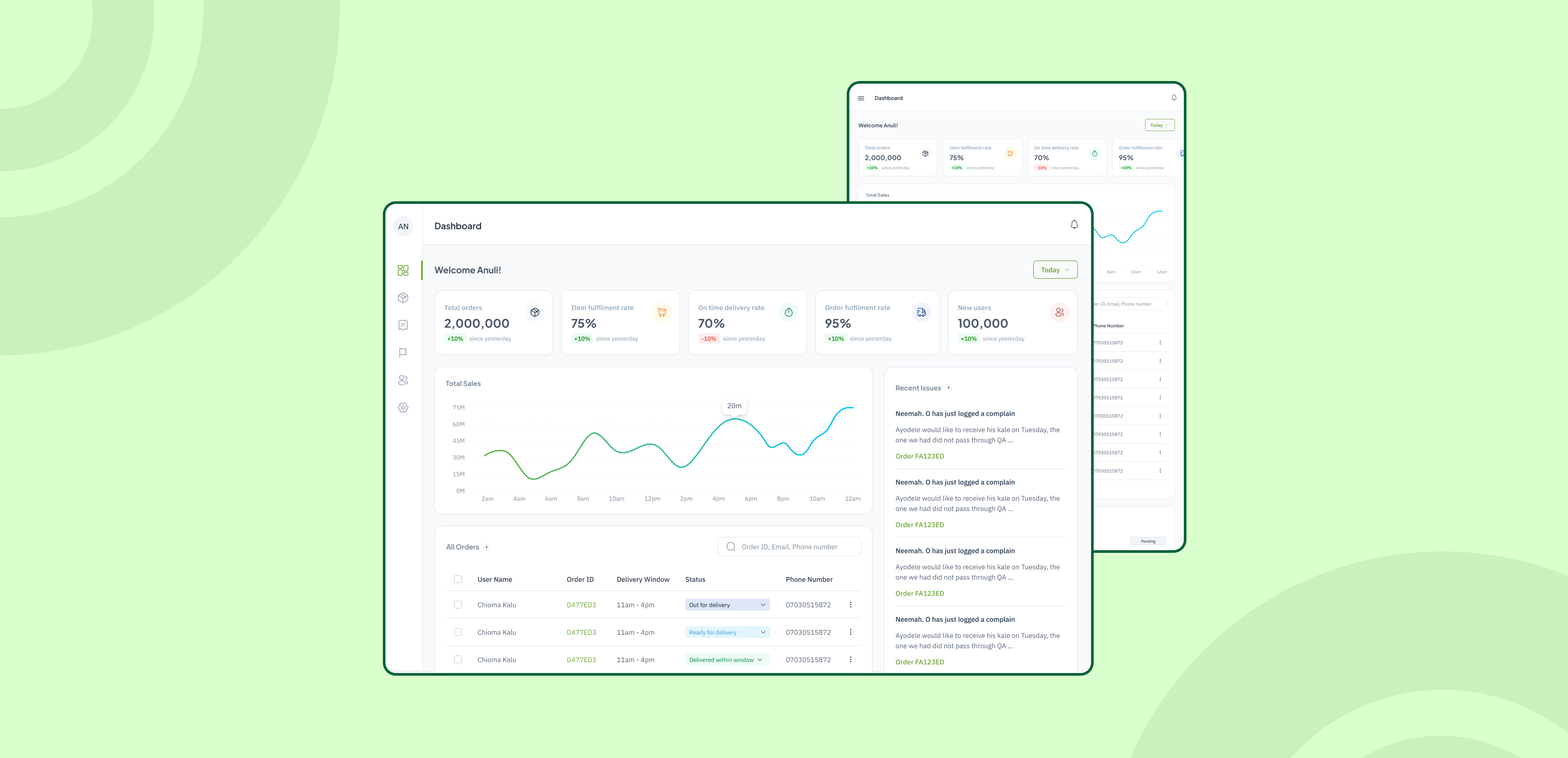

Dashboard

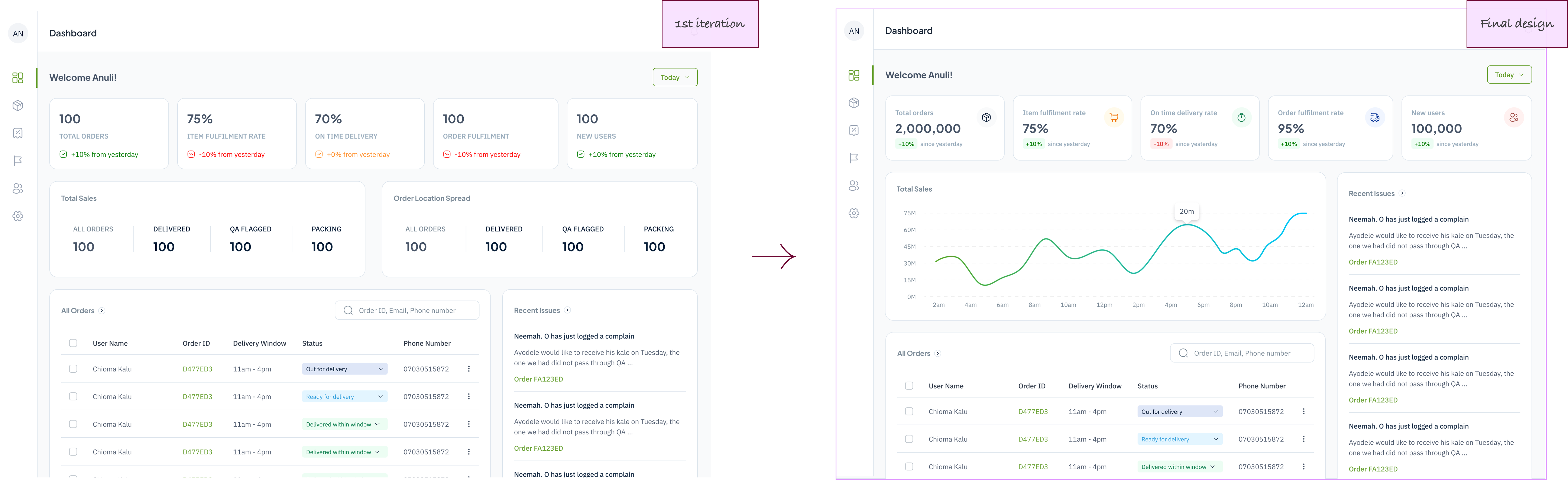

The dashboard provides a real-time overview of order statuses, enabling all teams to see what is happening at each stage of the fulfillment process. This eliminates the need for constant updates between teams and ensures everyone has access to the same information.

The dashboard

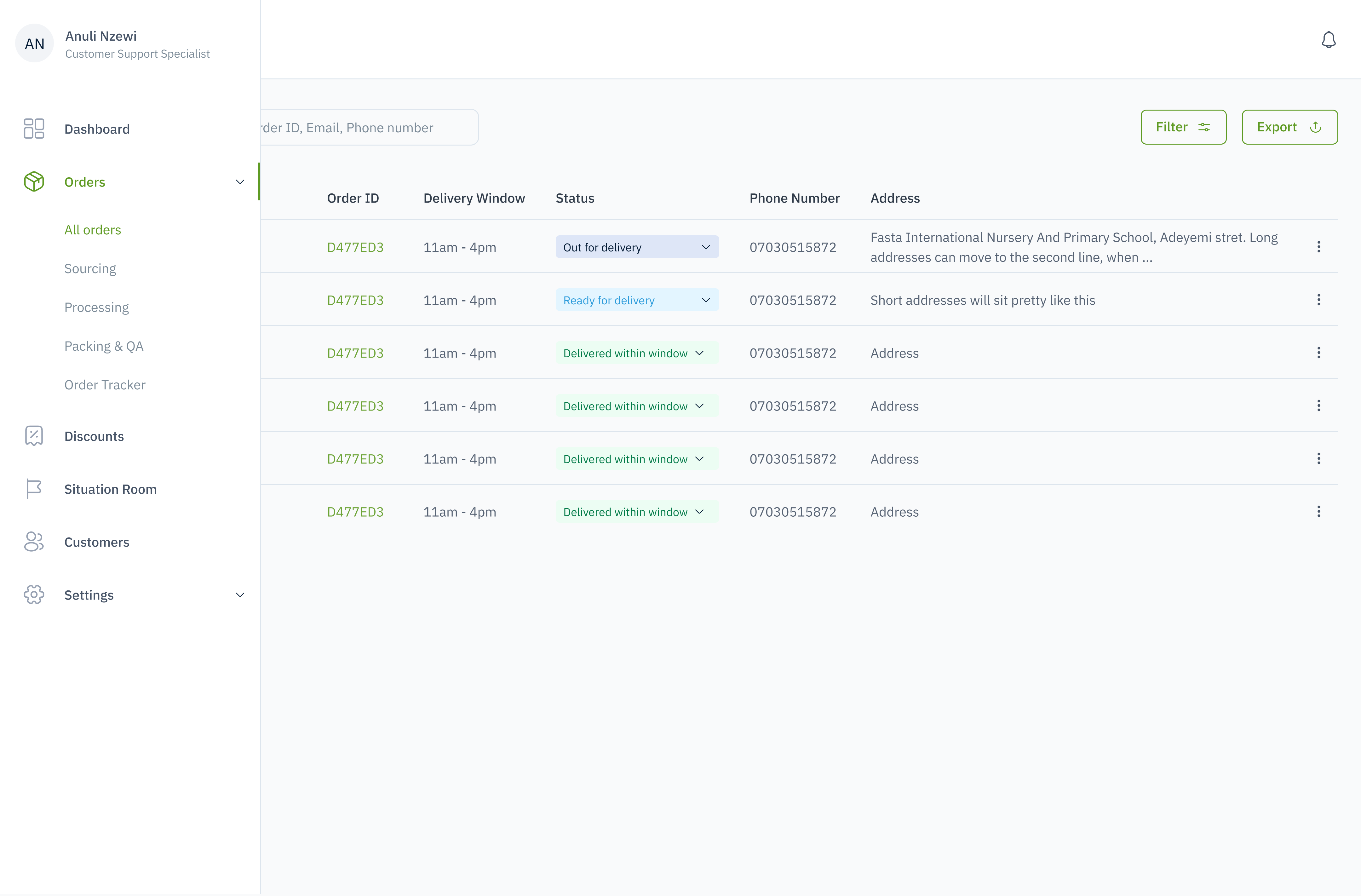

Order Management System

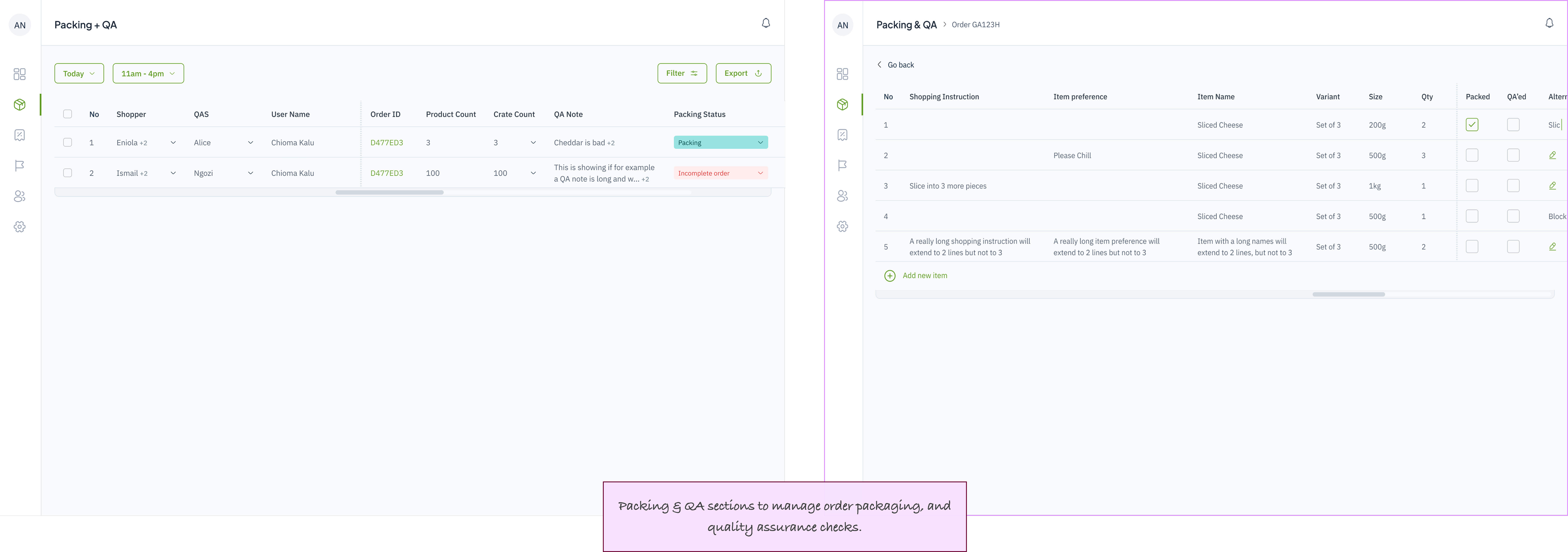

Limelight’s order management system is divided into clear sections: Sourcing, Processing, Packing & QA, and Order Fulfillment. Each section tracked the status of orders and allowed teams to easily see where bottlenecks were occurring.

The Orders section

The Packing section

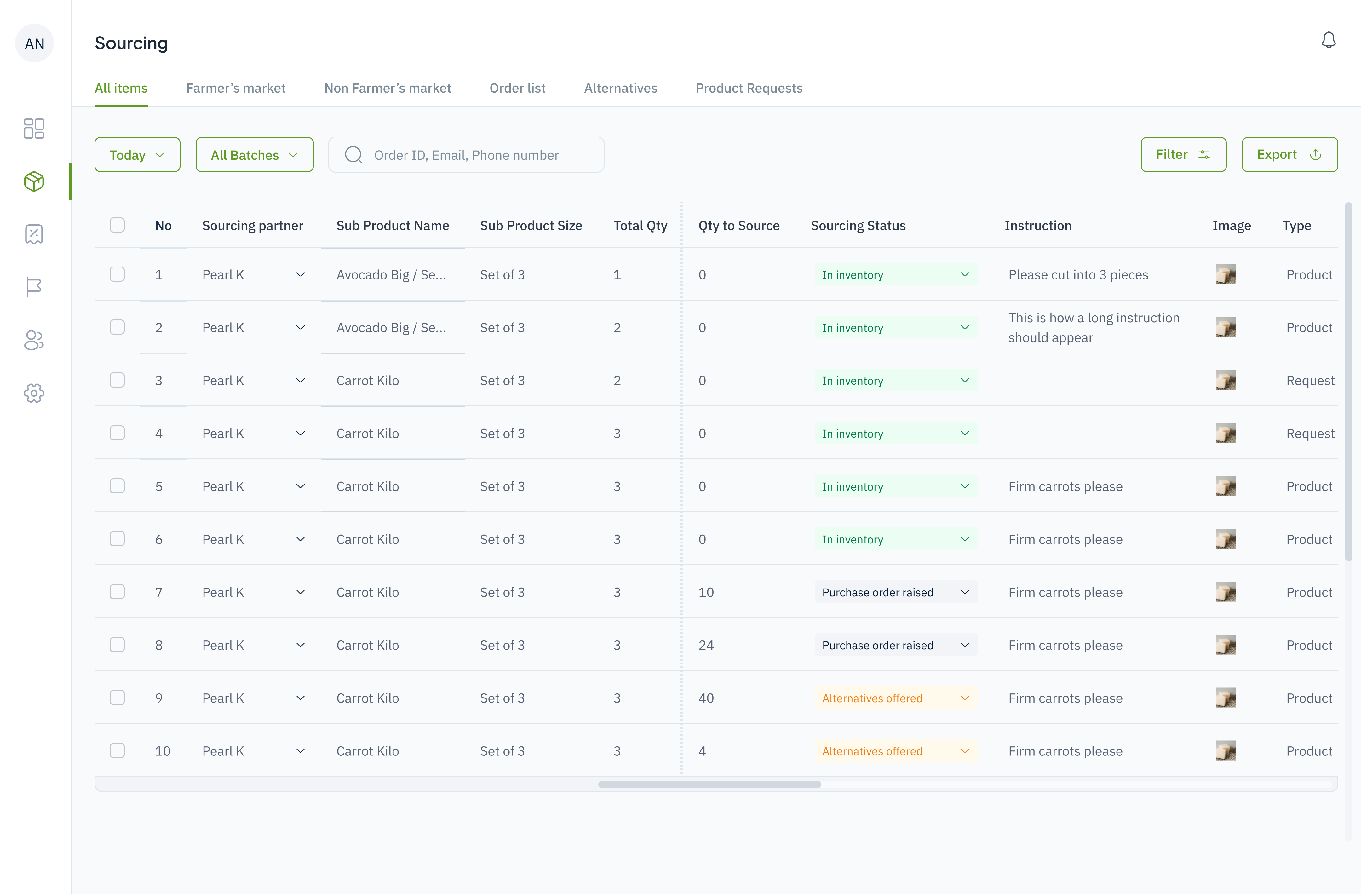

Inventory Integration

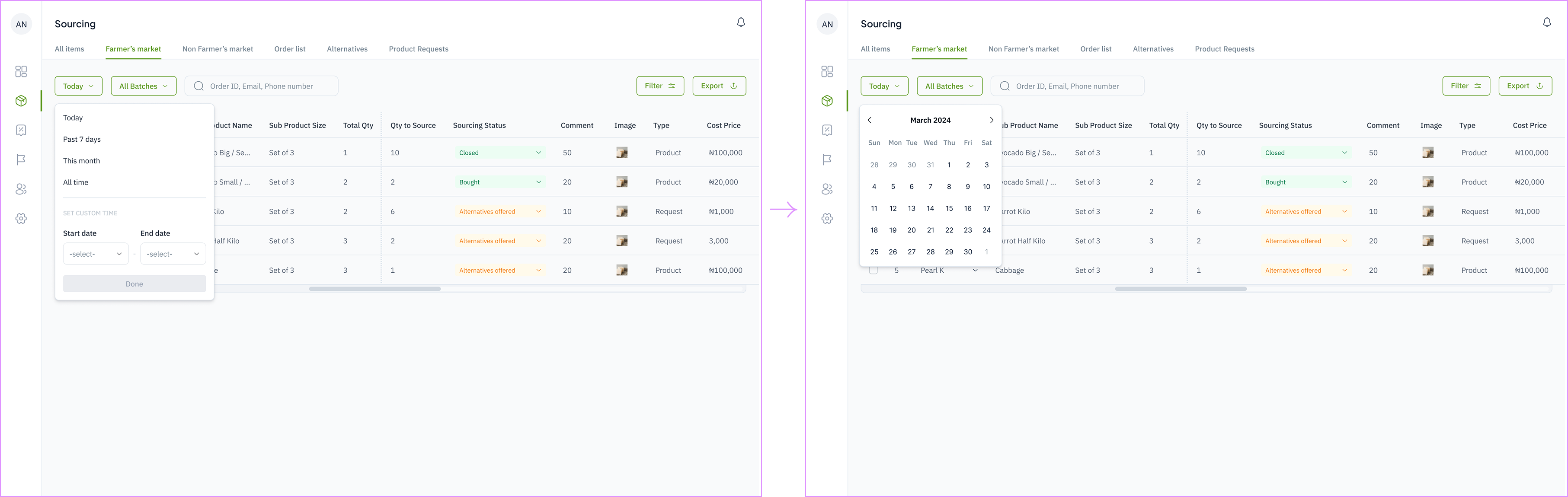

To solve the issue of inventory inaccuracies, Limelight integrates with the inventory management system. This allows the system to automatically calculate how much stock is needed based on daily orders, reducing errors and ensuring inventory levels are always up to date.

The sourcing section which is synced with inventory

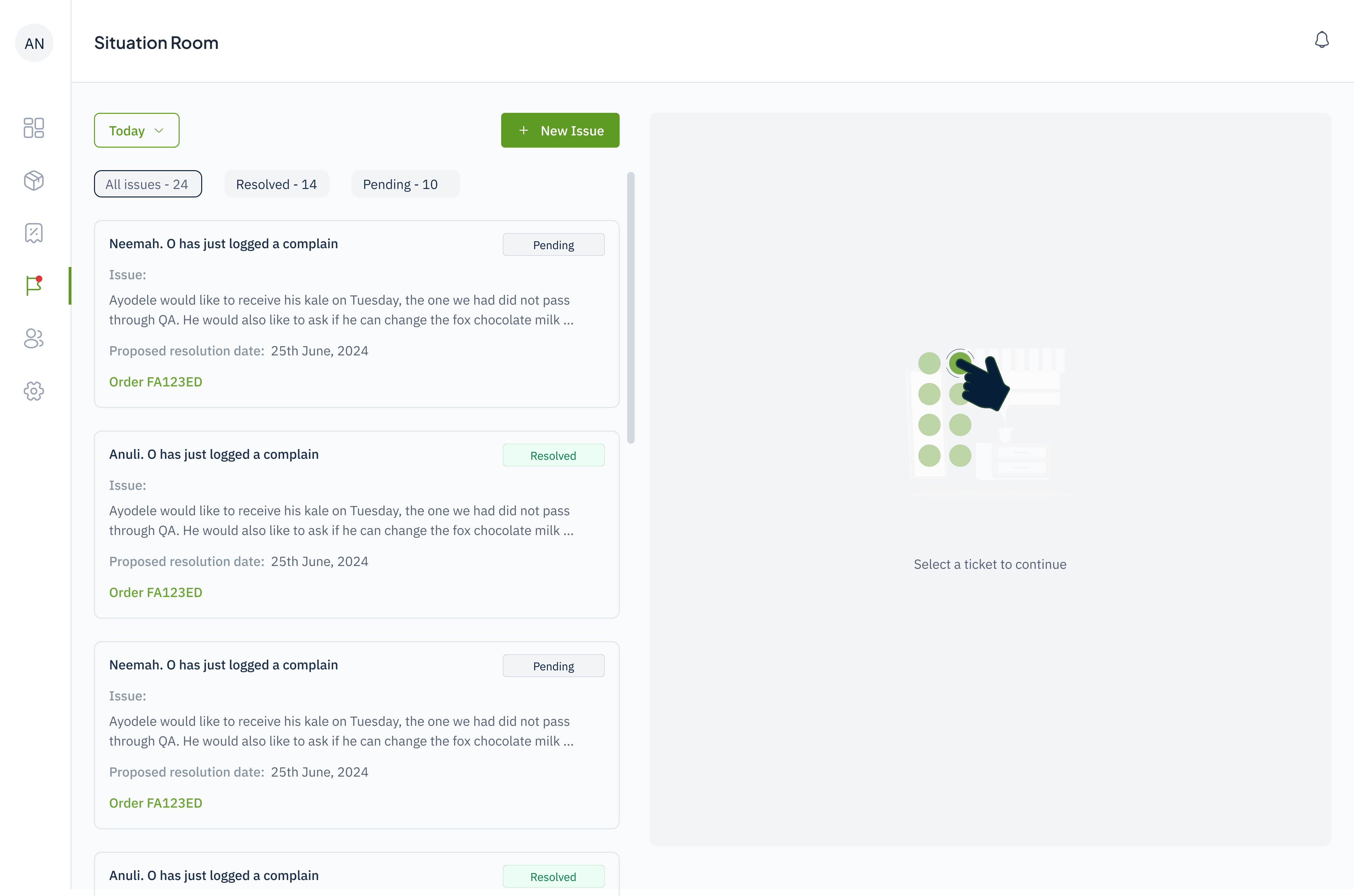

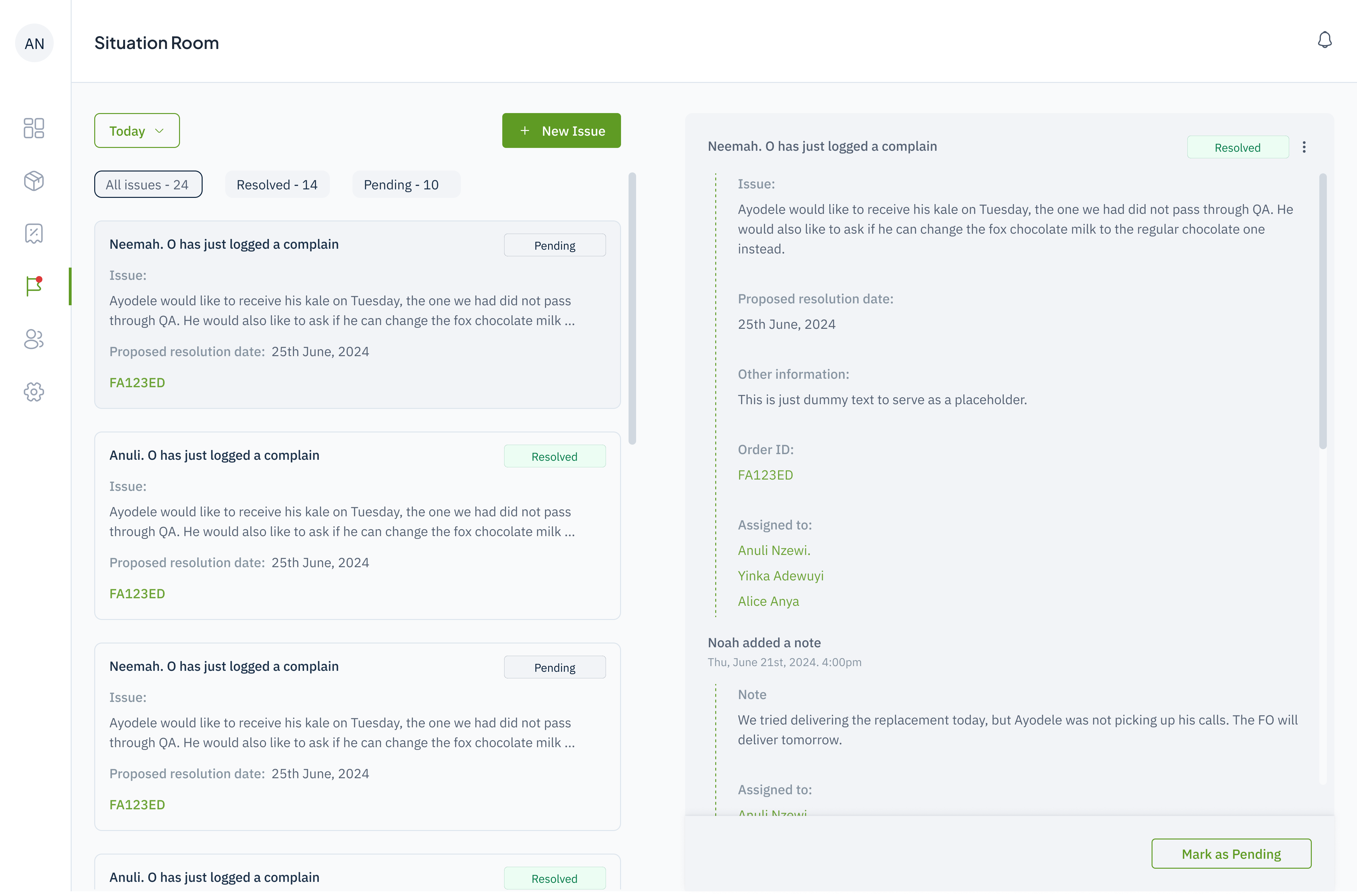

The Situation Room

The Situation Room replaced Slack as the main communication hub for the customer support team. It allows teams to log and track customer issues in real time, providing greater context and improving collaboration.

Situation room - No issue selected

Situation room - Issue selected

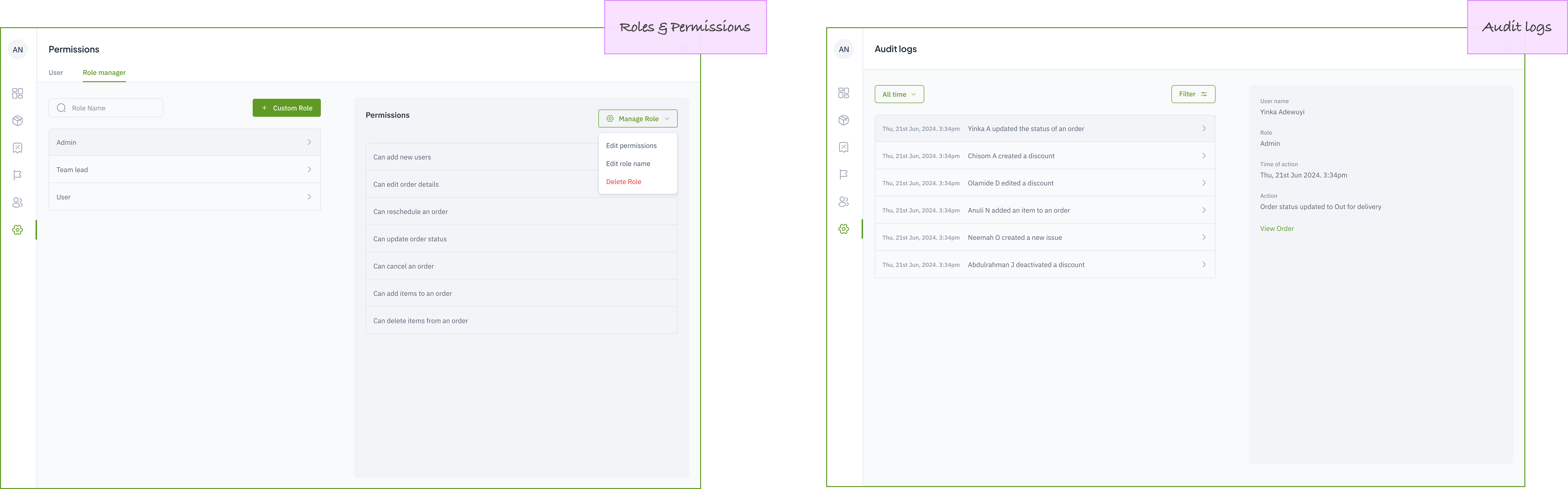

Roles, Permissions, and Audit Logs

We introduced a robust system of roles and permissions, allowing administrators to restrict access to specific data based on user roles. The audit logs tracks every change made in the system, providing accountability and ensuring that unauthorized changes are easily traced.

Permissions section - Users

Prototype

Limelight prototype

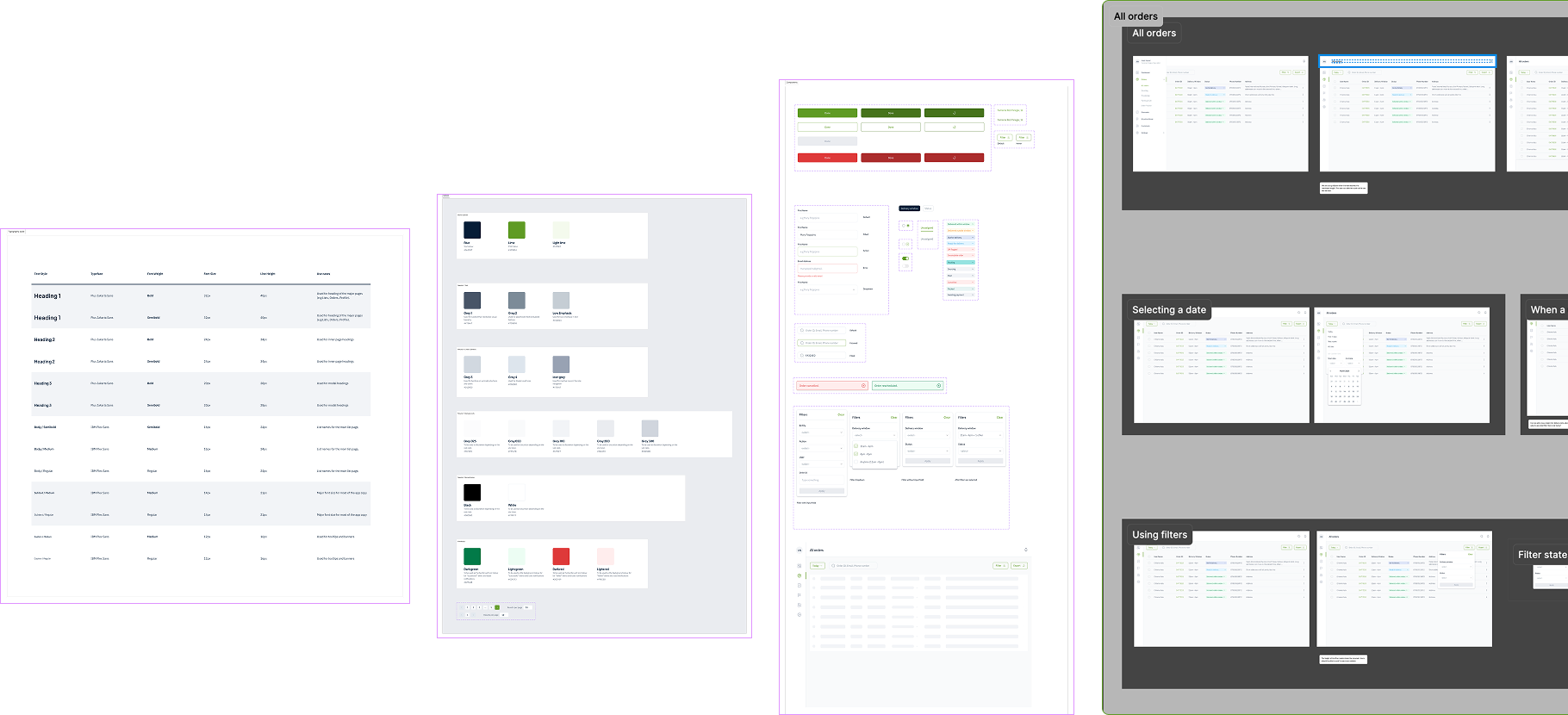

Developer handoff assets

Developer handoff

TESTING & ITERATIONS

After working on the design, I conducted demos and usability testing sessions with stakeholders across operations, enginering and customer support. From these conversations, we made some updates to the design to improve the accuracy and experience.

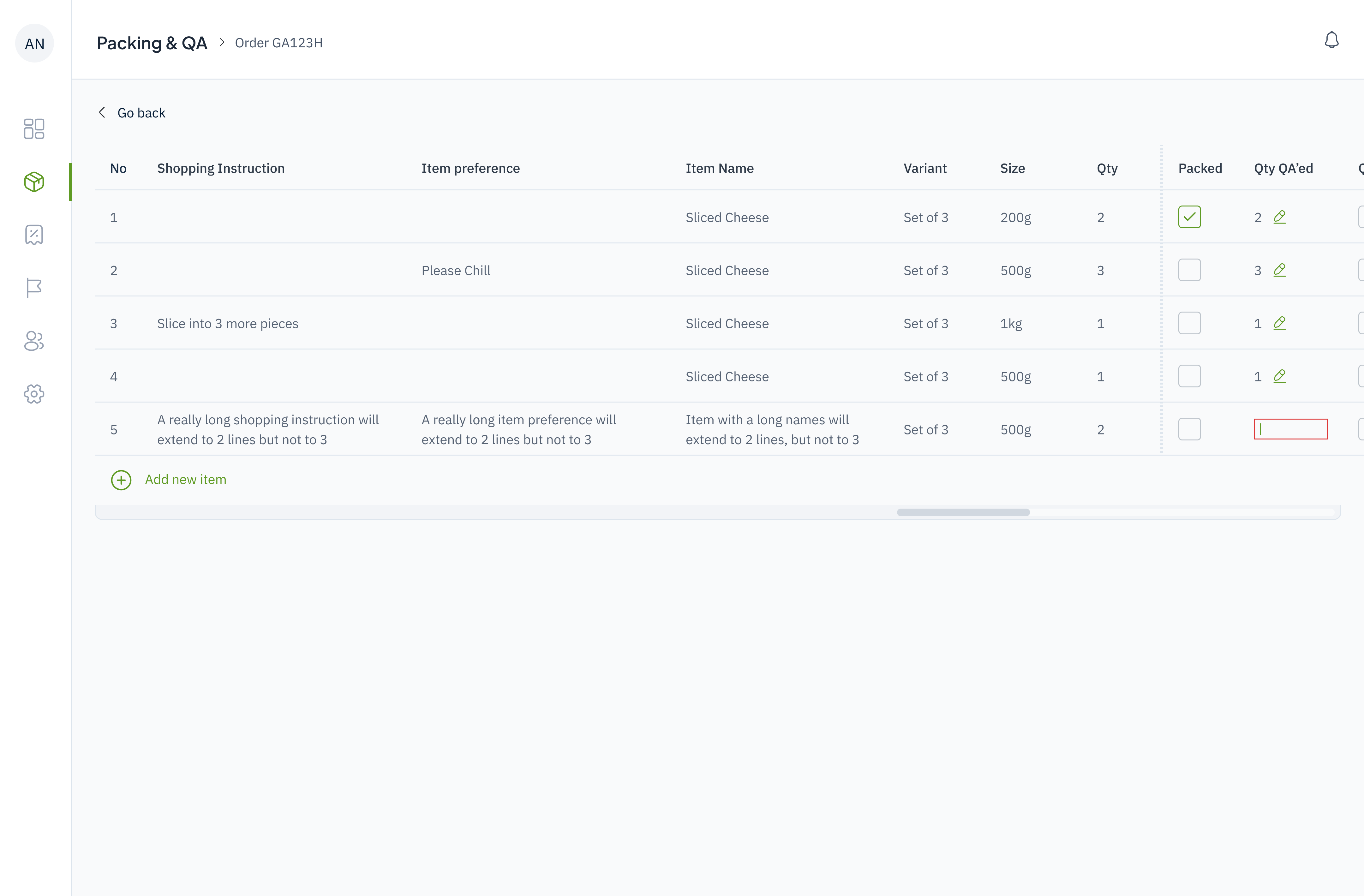

Introduced a quantity QA’ed column

This was added to address inventory discrepancies that were caused by returned items. This ensured that only the items deemed fit for delivery by the QA team were subtracted from inventory, preventing discrepancies and improving inventory reconciliation.

Quantity QA'ed column in the packing section

Swtiched the date filter from multi-entry to single entry

This was switched to address an engineering limitation.

Date filter switched from multi to single select

CHALLENGES

Feature Prioritization in a Resource-Constrained Environment:

With a tight timeline and constrained engineering capacity, we had to carefully prioritize building only the highest-impact features first, such as automating inventory reconciliation and centralizing order tracking, while deferring less critical features for future phases.

Ensuring User Adoption Across Diverse Teams:

Achieving adoption was challenging because multiple teams were accustomed to different existing tools and workflows. To address this, we engaged stakeholders early, involved them throughout design iterations, and crafted intuitive onboarding experiences tailored to each team’s needs to build trust and encourage smooth transition.

Complexity of Inventory Accuracy:

Testing revealed previously unrecognized complexities, such as returned items affecting stock counts and discrepancies between packed and QA-approved quantities. To tackle this, we introduced the “Quantity QA’ed” column and refined inventory syncing logic to ensure only verified items affected inventory, greatly improving accuracy.

Communication System Replacement:

Migrating communication from Slack to the new Situation Room required careful design to replicate needed workflows while improving issue tracking and context. We focused on reducing disruption by aligning the new tool closely with the support team's operational needs.

IMPACT

CHECK OUT MY NEXT PROJECT

Virtual Terminals

Enhancing the in-person payment experience

Design. Usability Testing

Content guide